Seeding Rate & Swath Module Operator's Guide

Contents

- System Operation Requirements

- Home and Control Screens

- System Setup

- Hardware Setup

- Additional Hardware

- System Settings

- Alerts

- Changing Crop and Seeds / Disk

- Using Hybrids

- Manual Test

- Diagnostics

- Appendix A

This guide is intended for use with limited release software 2025.1.0 and its variants. Due to the nature of the limited release software update process, screenshots and descriptions provided in this guide may differ from the current version. Updates are made to this guide as often as possible. To download the most recent version of Gen 3 software, visit 2020.ag

Rate / Swath Control Operation Requirements:

- Seeding system configured on the 20|20.

- Default Rate set.

- Speed source active.

- CCM master plant switch in the up position.

- Implement must read lowered.

- Seeding system enabled.

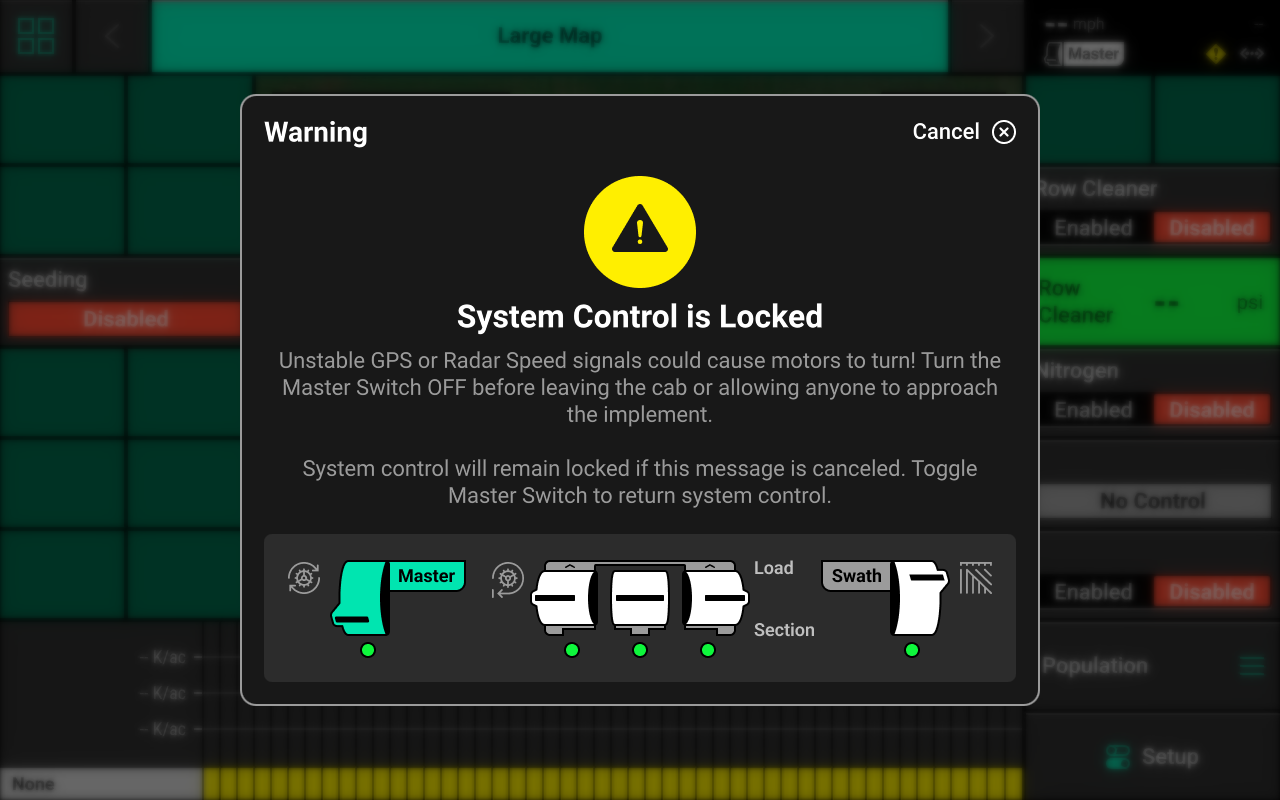

Safety Warning

If any control product is configured on the 20|20 display, the system will require a CCM and will prompt the user to toggle the Master Plant switch on the CCM before any control products may be used. This warning is triggered any time the system is booted up, and when the system has traveled for more than half a mile. Pressing cancel will bypass this warning. No control systems will operate until the Master Plant switch is toggled. The Master Icon will be present in the top right of the 20|20 screen in the Status Center if the safety warning was bypassed.

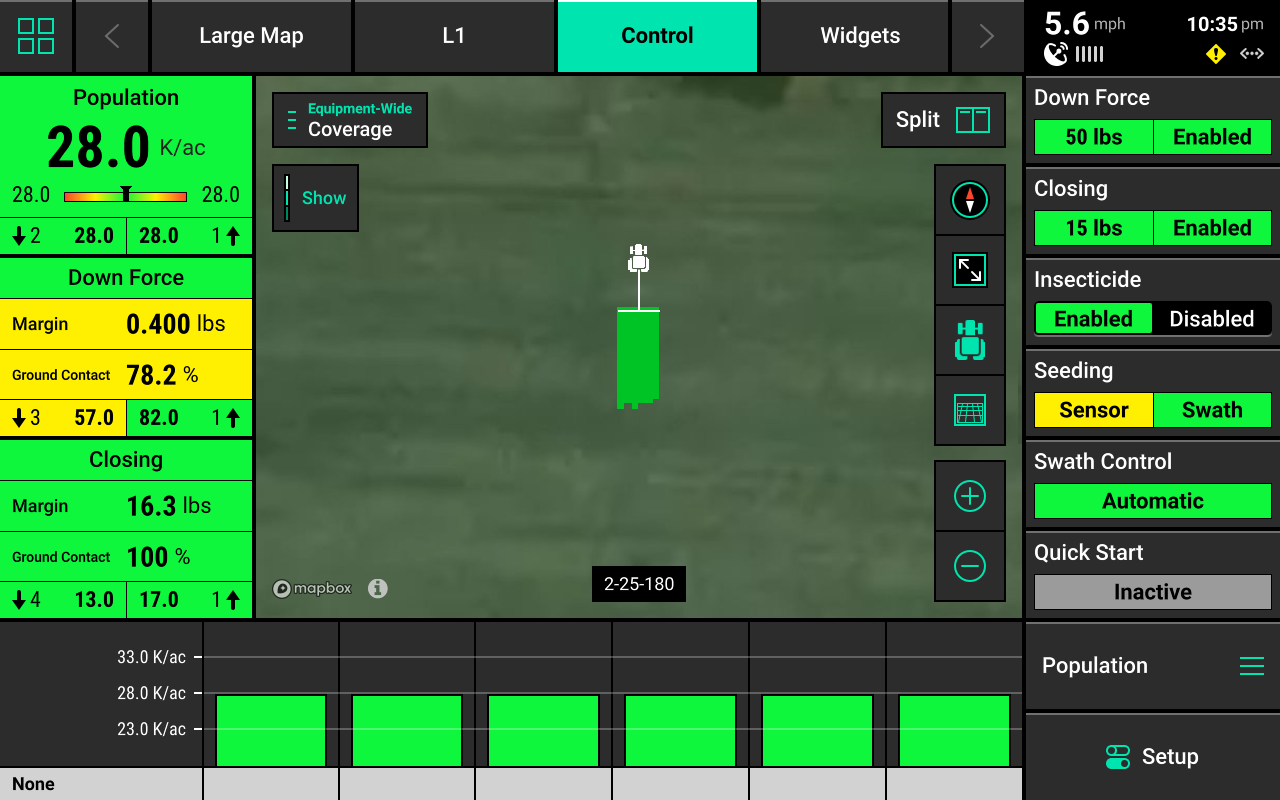

Home and Control Screens

Home Screen

The home screen displays information for controlling and mapping the Seeding system.

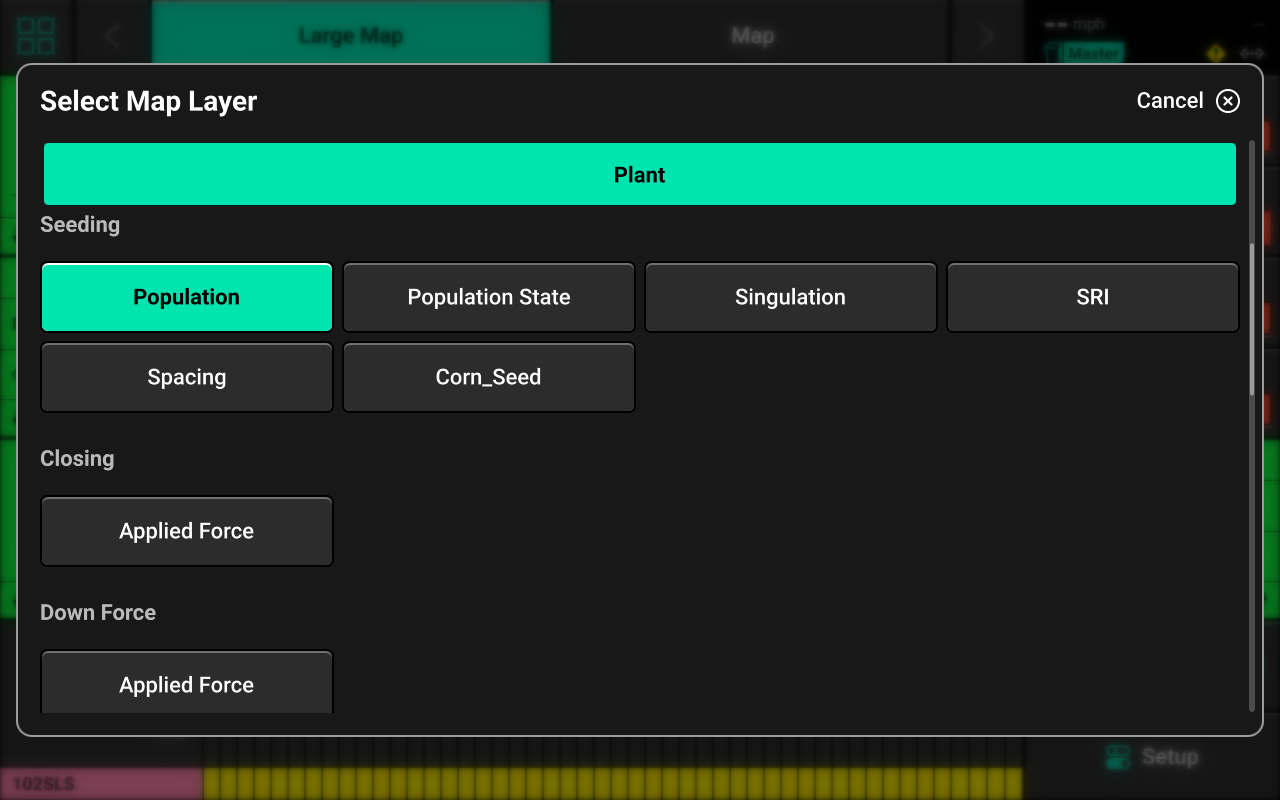

Rate / Swath Control Mapping

Different maps are available for the Seeding system. To view the map layer options, press the current layer name that is displayed in the top left corner of the map. A list of all available maps will be displayed.

- Population — Displays planted population.

- Population State— Displays alert / alarm readings.

- Singulation — Displays seed singulation results.

- SRI — Displays Seed Release Index readings.

- Spacing — Displays average seed spacing.

If a seeding prescription or field boundary is assigned to the active field, the prescription / boundary file will be available as a map layer.

See the 2025.1.x Gen 3 Operator's Guide for definitions of these and other metrics.

Control Widget

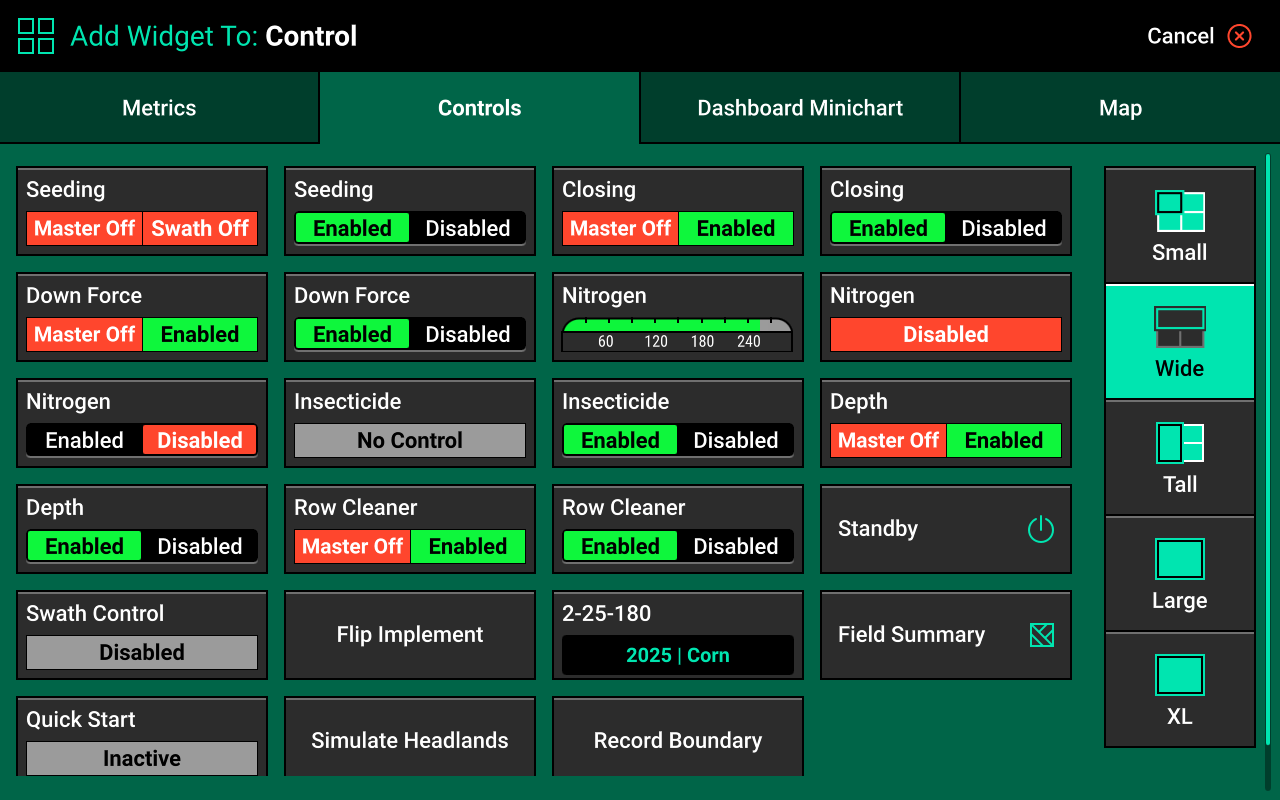

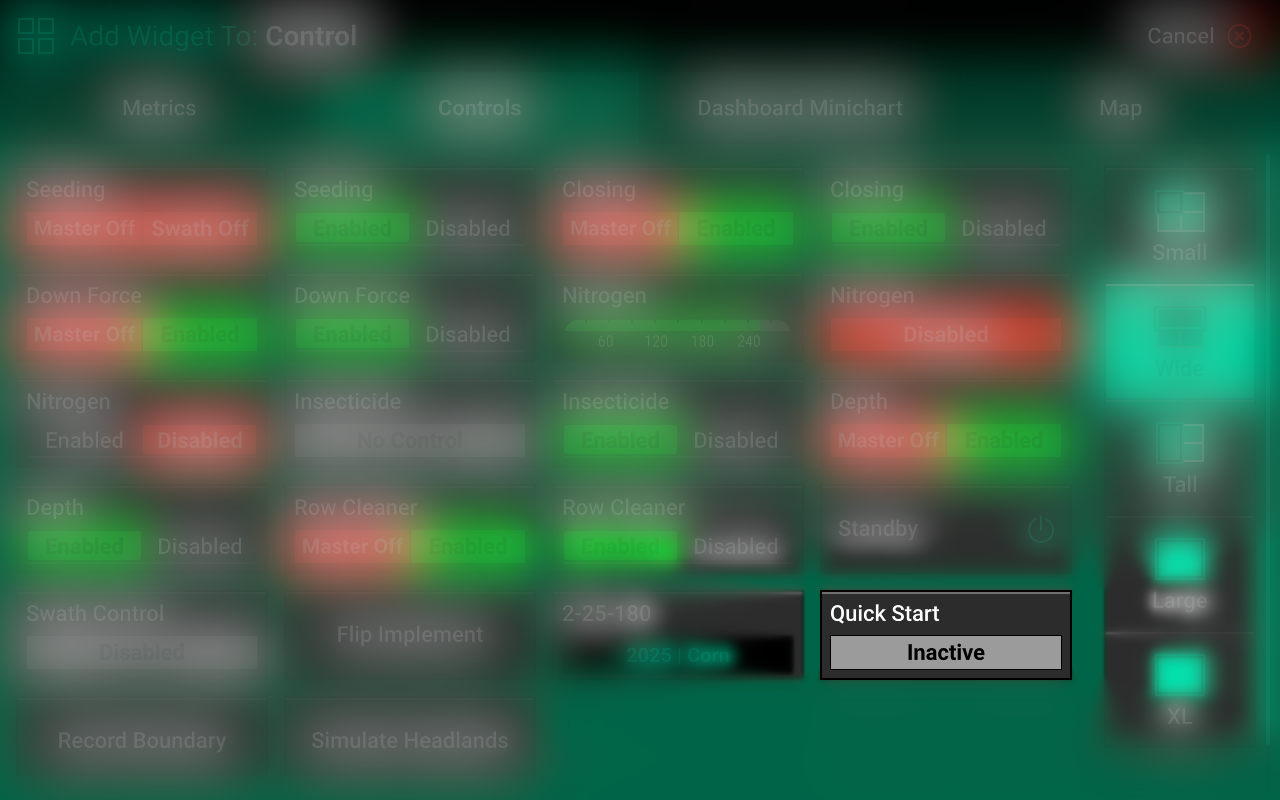

A Control widget for the Seeding system must be placed on the home screen before the system will function. Press the Four Squares in the top left, then press Add Widget + in the bottom right and select Controls to view options. Some Control widgets include a toggle which allows the user to enable or disable the system without opening the Control screen. Other control widgets include quick adjust buttons for population change. Press the different sizes on the right to view all options.

Control Indicators

- Enabled : The system is ready to plant.

- Disabled : The system will not plant. To enable the system, toggle the system to enabled using the control widget.

- Lifted : The system will not plant due to lift switch reading.

- Master Off : The master plant switch on the CCM is off or the safety warning was bypassed. The system will not plant.

- Sensor : The system is using a sensor (e.g. SmartFirmer) for population control.

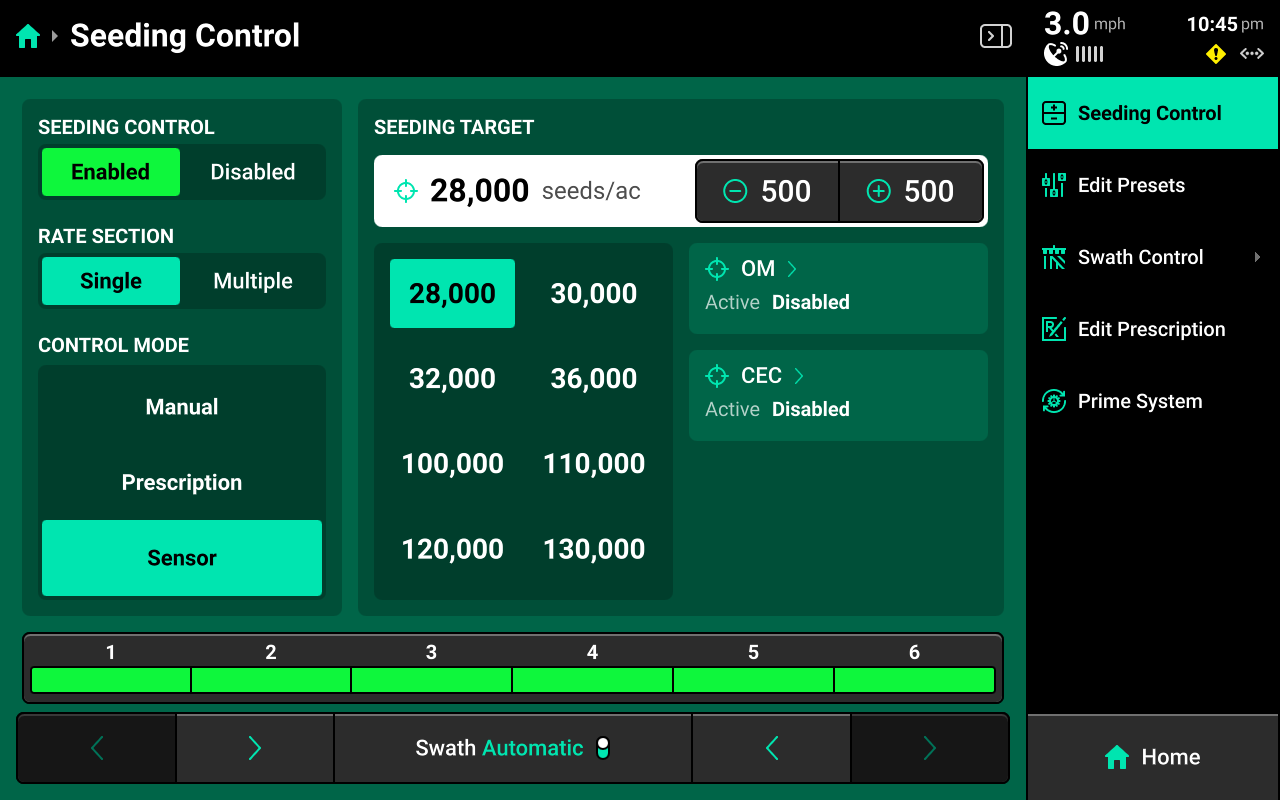

Control Screen

Once the Control widget has been added to the Home Screen, press it to open the Control screen.

Control Mode

Select the desired Control Mode to control population manually, by prescription, or by SmartFirmer readings.

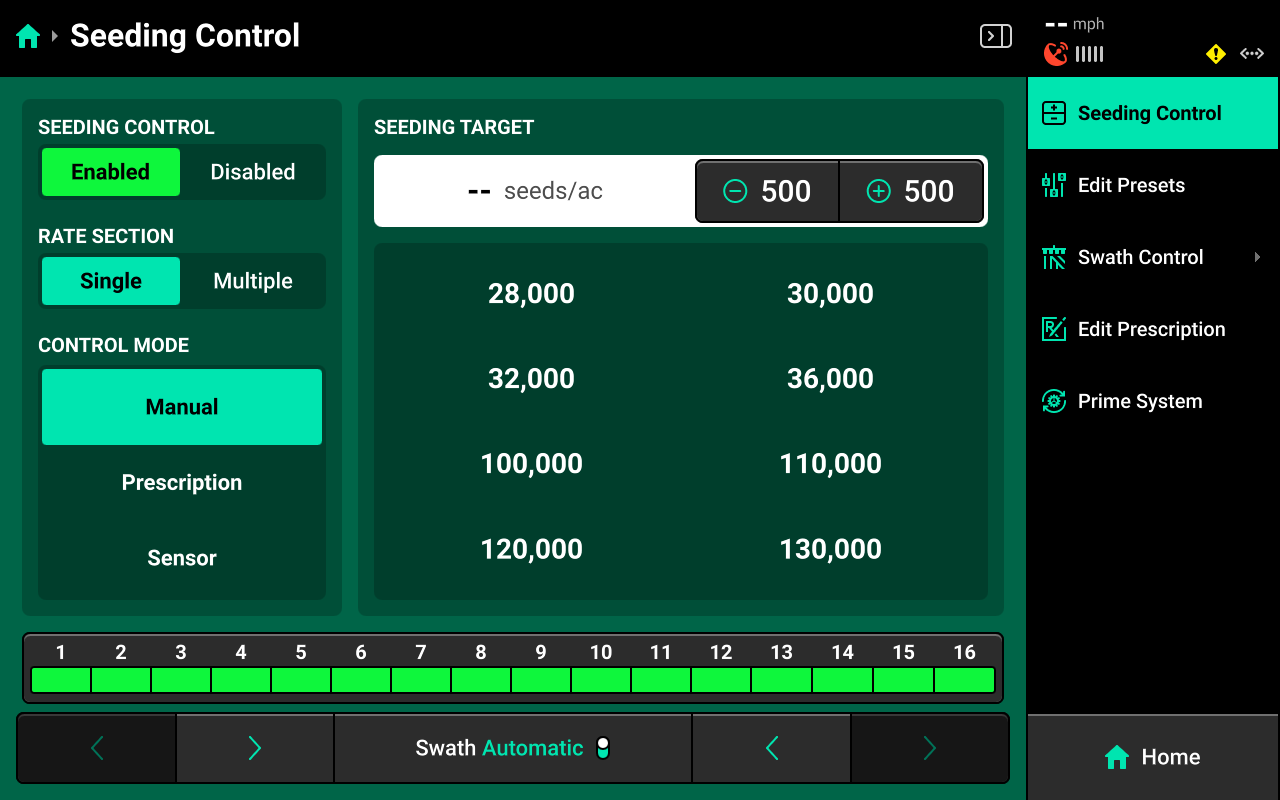

Manual Control

Allows the user to manually select population for one or more rate sections. This setting ignores any assigned prescriptions.

Rate Sections

- Single : One population across all rows.

- Multiple : Up to 4 different populations across preconfigured sections of the planter. See System Settings in this guide for more details.

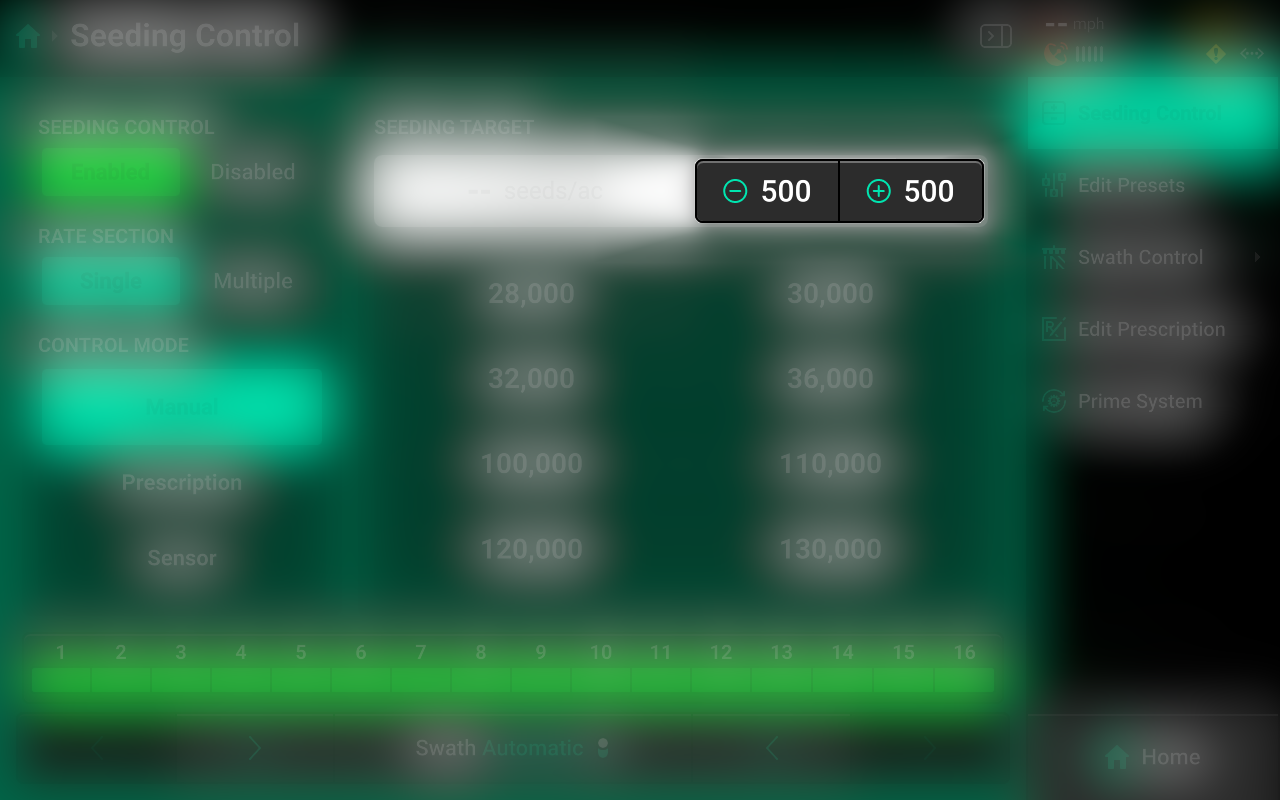

Select the desired section mode and set the desired population(s) using the presets in the center. Press the number displayed under Seeding Target in the center to manually enter a population (Single rate section only). Press Edit Presets on the right to modify the table of preset population values.

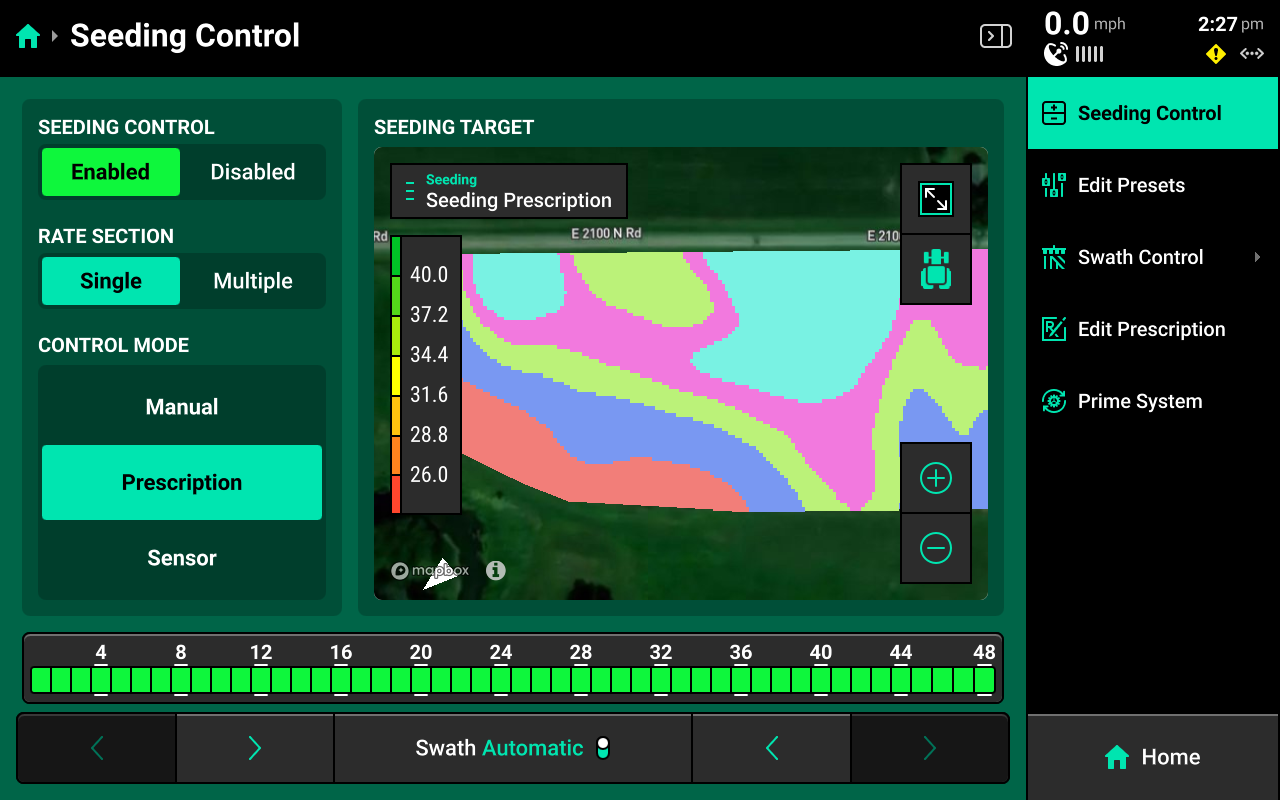

Prescription Control

Sets the system to control using the prescription assigned to the active field. A map of the prescription will be displayed in the center. Press Edit Prescription in the navigation menu to open the prescription edit screen.

If a seeding prescription is assigned to the active field, Prescription mode will be selected by default.

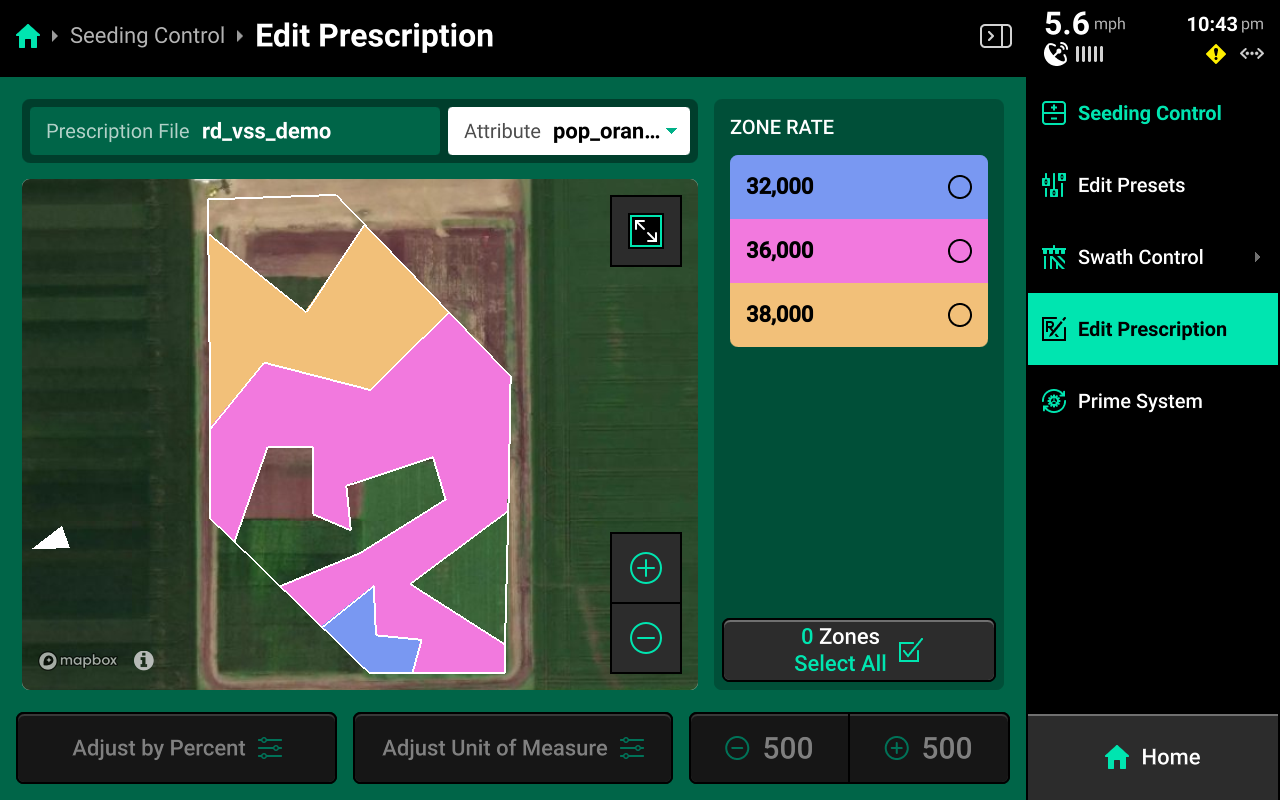

Edit Prescription

Select the desired prescription attribute to edit using the dropdown box above the map, then select the desired zone rates and use the buttons at the bottom to adjust those rates by a percent or by a preset value. Press Adjust Unit of Measure to switch between Imperial and Metric measurements for the selected zones.

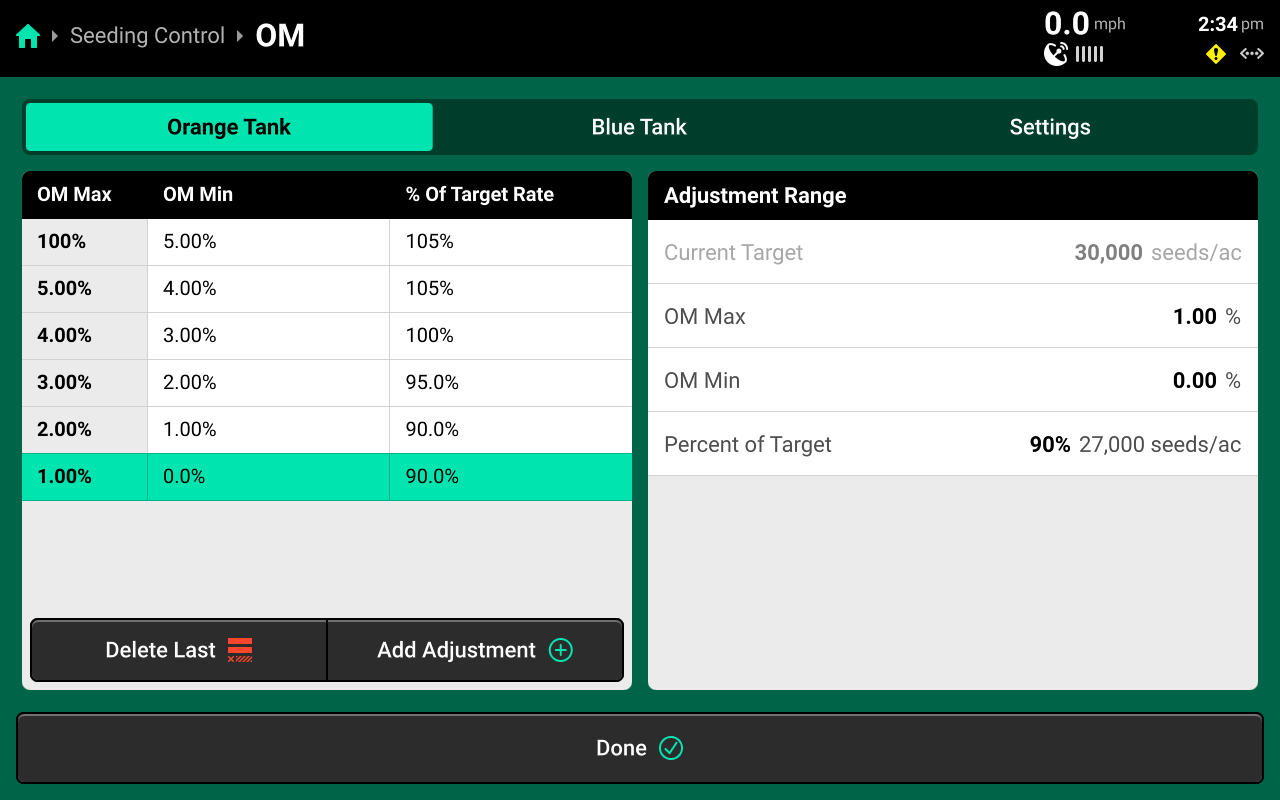

Sensor Control

Sets the system to control to SmartFirmer readings by user-defined parameters. Press OM or CEC in the center to configure either Organic Matter or Cation Exchange Capacity control parameters.

Select a Range in the left window, then use the settings in the right window to set values and desired rate for that range. To fine-tune control, press Add Adjustment + in the lower left window to add another range. Each range must be configured manually. Use the Settings tab at the top to toggle OM / CEC control between Enabled and Disabled.

It is required to add a max value of 100% to the first range, and a min value of 0% to the last range as "control layers" for the system. The max value of each range must be equal to the min value of the preceding range. See the above image for correct control layer setup.

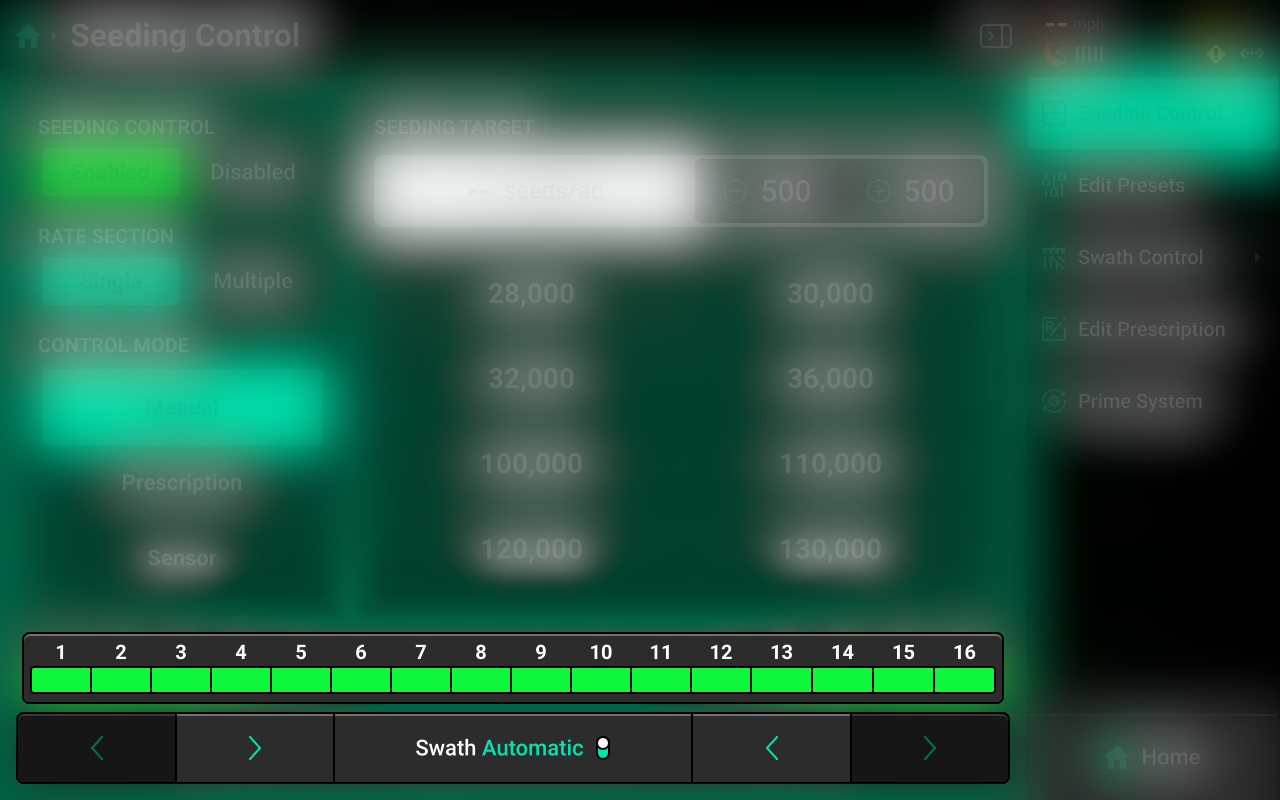

Manual Swath Control

A Swath Control Bar is displayed at the bottom of the control screen. Press any row in the bar to swath that row off and engage Manual Swath Mode. Rows may also be clutched off from left-to-right or right-to-left using the arrows below the Swath Control Bar.

In Manual Swath Mode, the 20|20 will no longer swath off to boundaries or coverage. To return to Automatic Swath Mode, press Swath Manual in the bottom center.

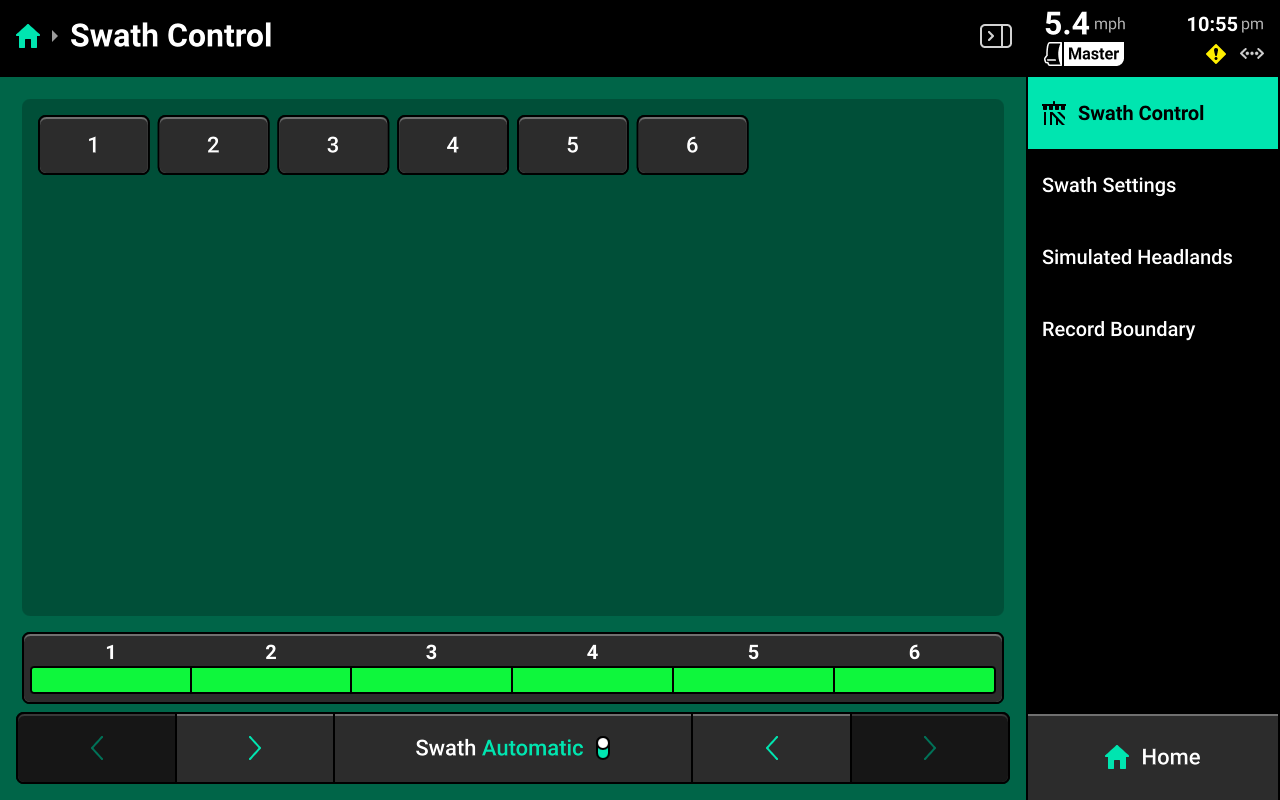

Swath Control Screen

The Swath Control Screen allows the user to manually swath rows on / off, configure a swath control plan, record a boundary, or simulate headlands. Use the table of rows rows off manually, or use the Swath Control Bar at the bottom using the procedure described in the previous section.

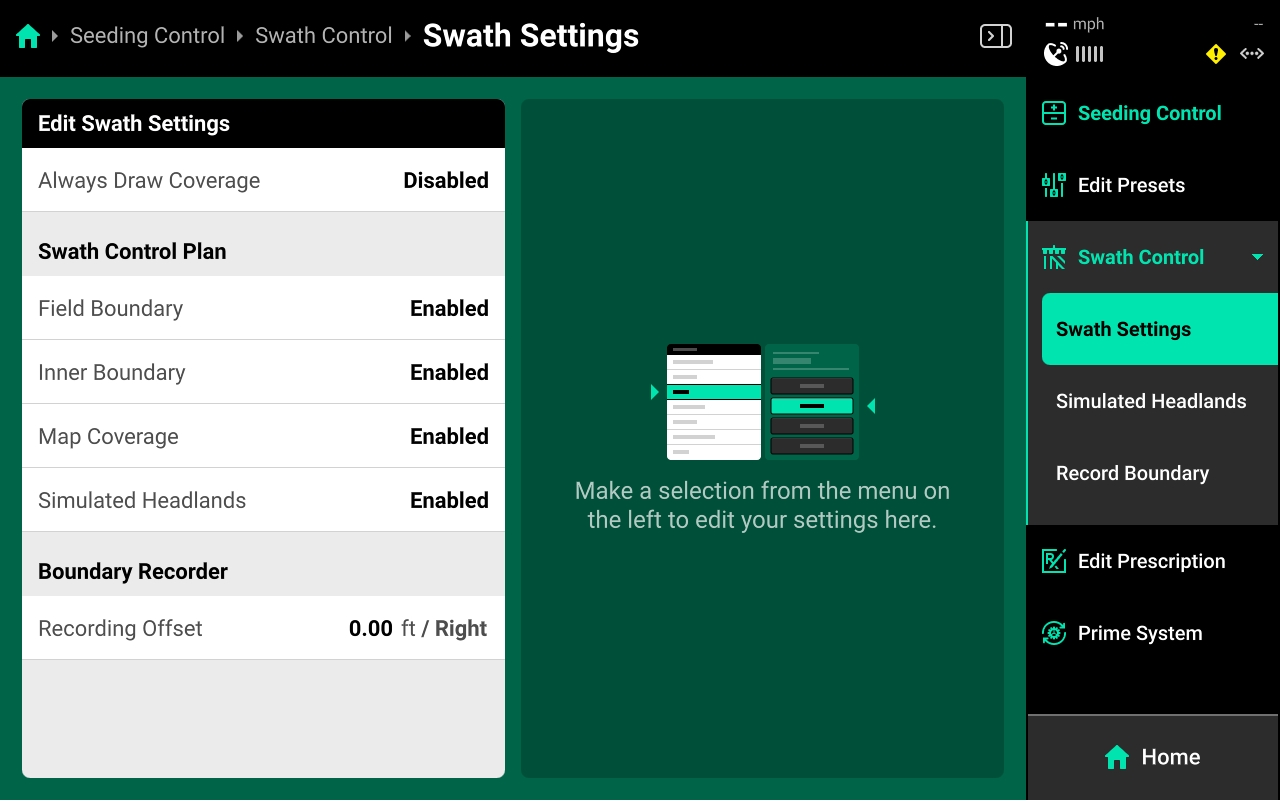

Swath Settings

Use these settings to determine how the 20|20 draws coverage, to change which parameters the 20|20 will use to swath on / off, or to enter an offset to use when recording boundaries.

The 20|20 will not swath off to any option under Swath Control Plan which is set to Disabled.

Setting Always Draw Coverage to Enabled will cause the 20|20 to draw coverage whether the implement is actively planting / spraying / etc. or not.

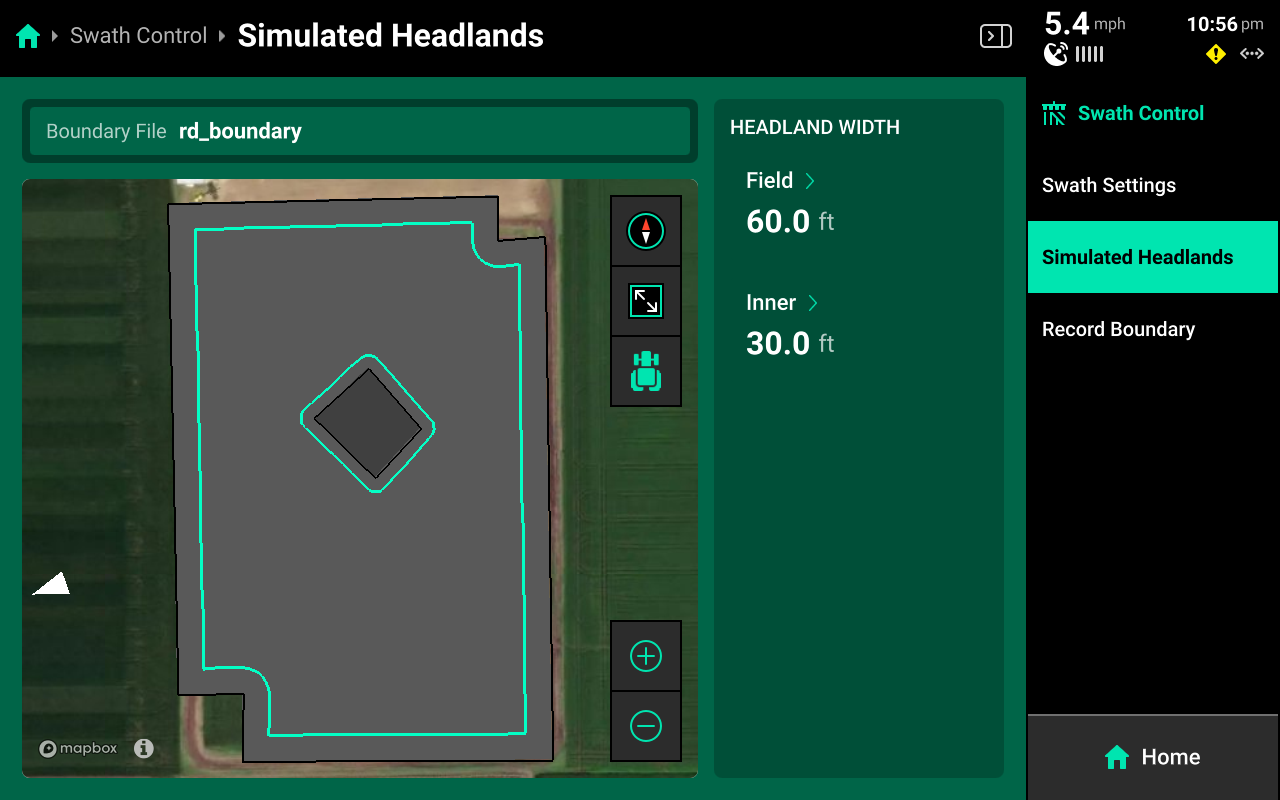

Simulated Headlands

Select a width for Field (Exterior) or Inner to set the simulated headland width for either option.

A Boundary file must be assigned to the field to enable simulated headlands.

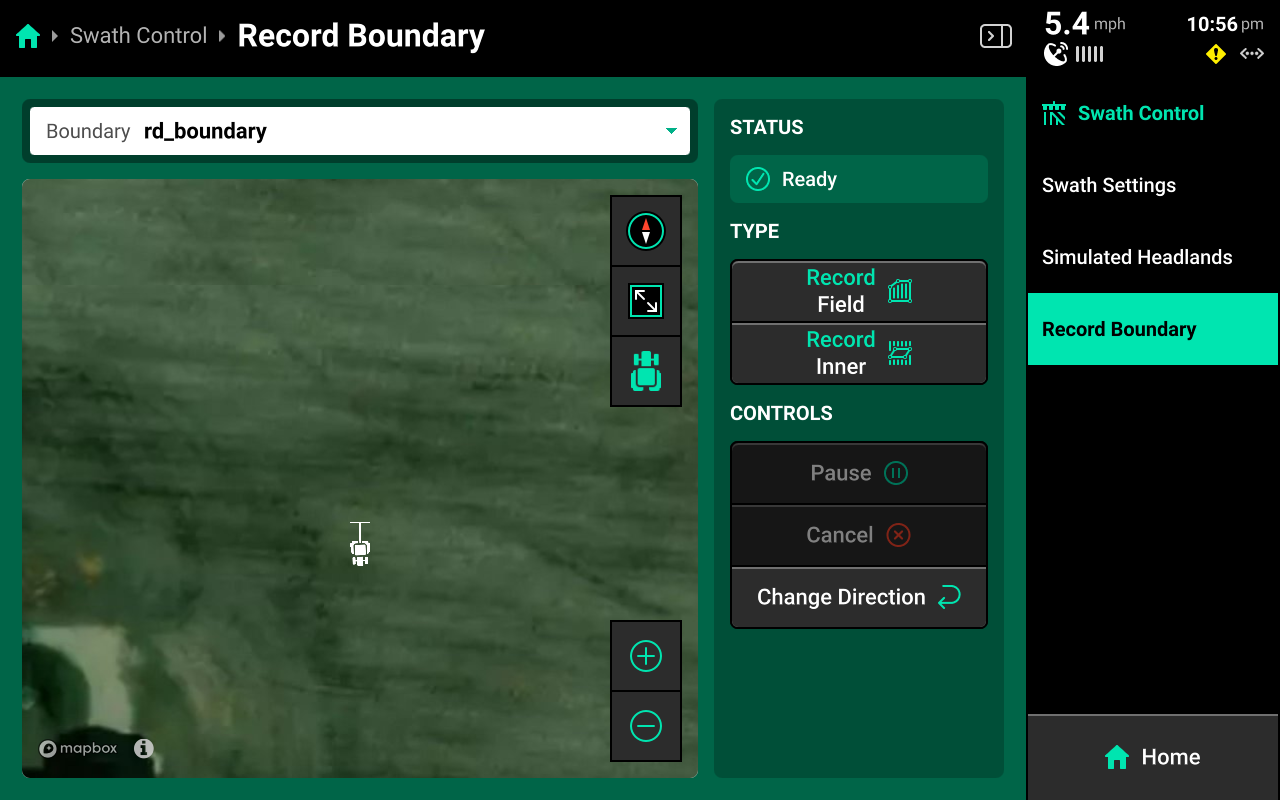

Recording Boundaries

Use the Record Boundary Screen and follow the process detailed below to record a boundary using the 20|20.

- Use the dropdown menu to select an existing boundary to rewrite, or create a new file name.

- Press Record Field (Exterior) or Record Inner to begin recording either type of boundary.

- Use Pause or Cancel to temporarily or permanently stop recording the current boundary. Use Resume to unpause.

- Use Change Direction to correct the tractor heading, if necessary.

- Press Save to keep the current recording.

To ensure maximum accuracy around outer field corners, press Pause after reaching an outer corner. Complete the turn, then back fully into the corner. Press Resume when the tractor is properly repositioned.

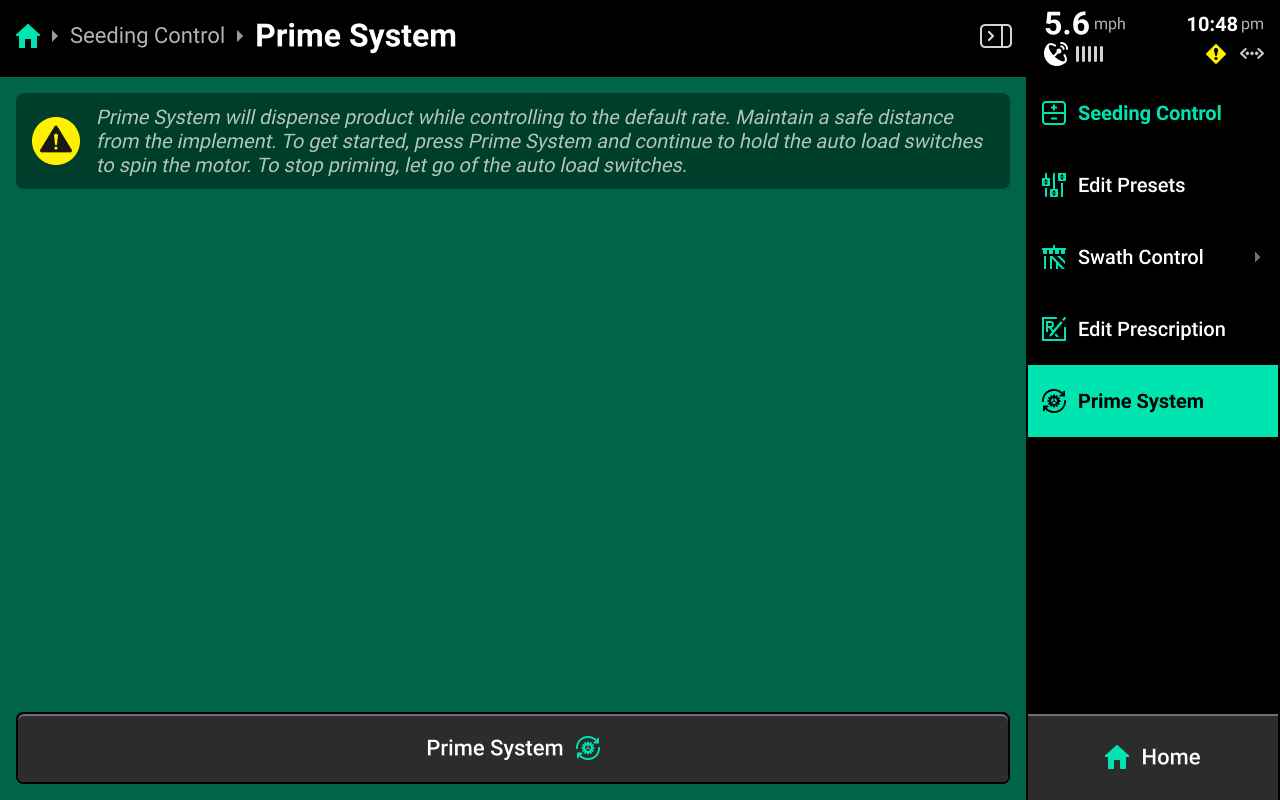

Priming the System

Press Prime System in the Navigation Menu to access the Prime System function. Press Prime System at the bottom of this screen to open a popup which instructs the user to hold both switches up to dispense product at the default population. The system will dispense as long as the switches are held up.

Product will only be dispensed for the specific system through which the Prime System function was accessed (e.g. priming the Seeding system will not cause liquid systems to dispense).

Quick Start

Add the Quick Start widget to use the quick start feature.

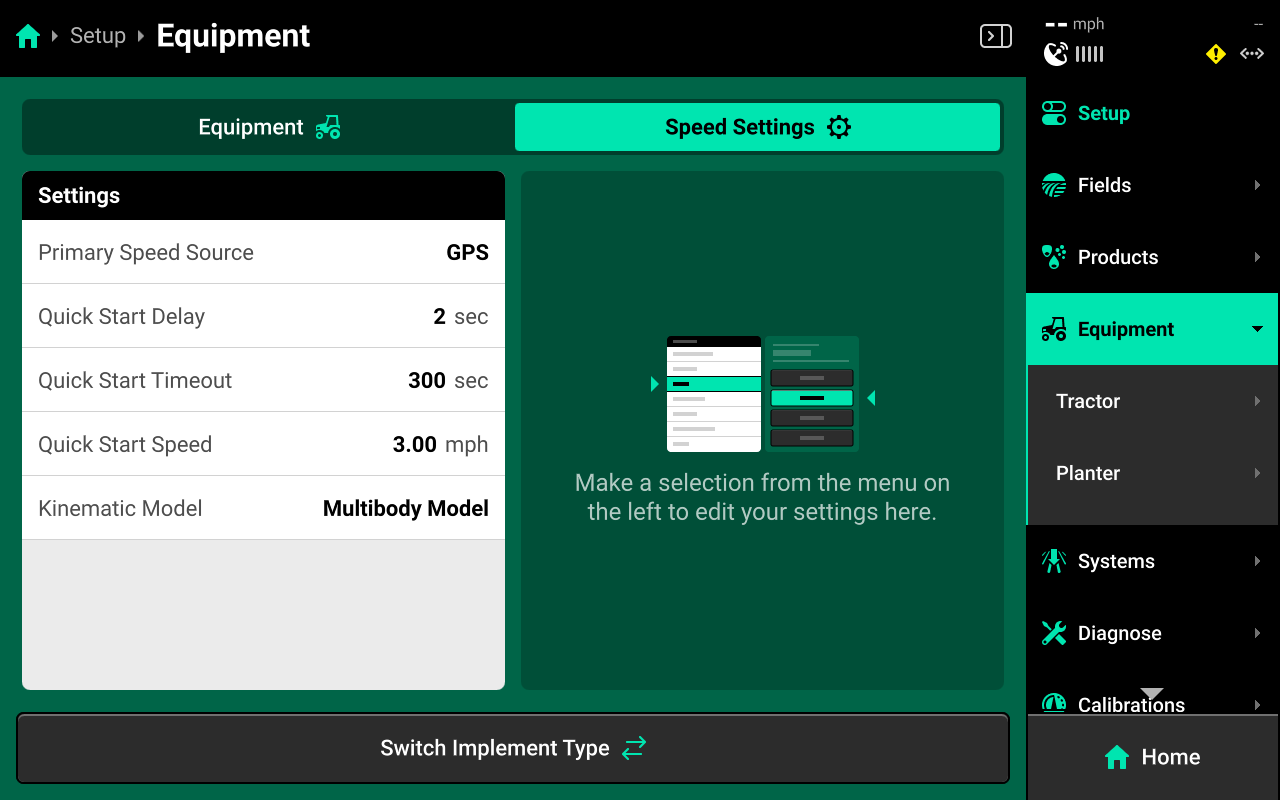

Once the widget has been added to the home screen, press it to initiate a countdown. When the countdown reaches 0, the system will begin dispensing all products at a simulated speed. It will continue to run until either the 300 second timeout is reached, or until the 20|20 registers speed from the primary speed source.

Timeout, Simulated Speed, countdown (Quick Start Timeout) and Primary Speed Source may be adjusted by navigating to Setup > Equipment and pressing the Speed Settings tab at the top. See the 2025.1.x Gen 3 Operator's Guide for more details.

System Setup

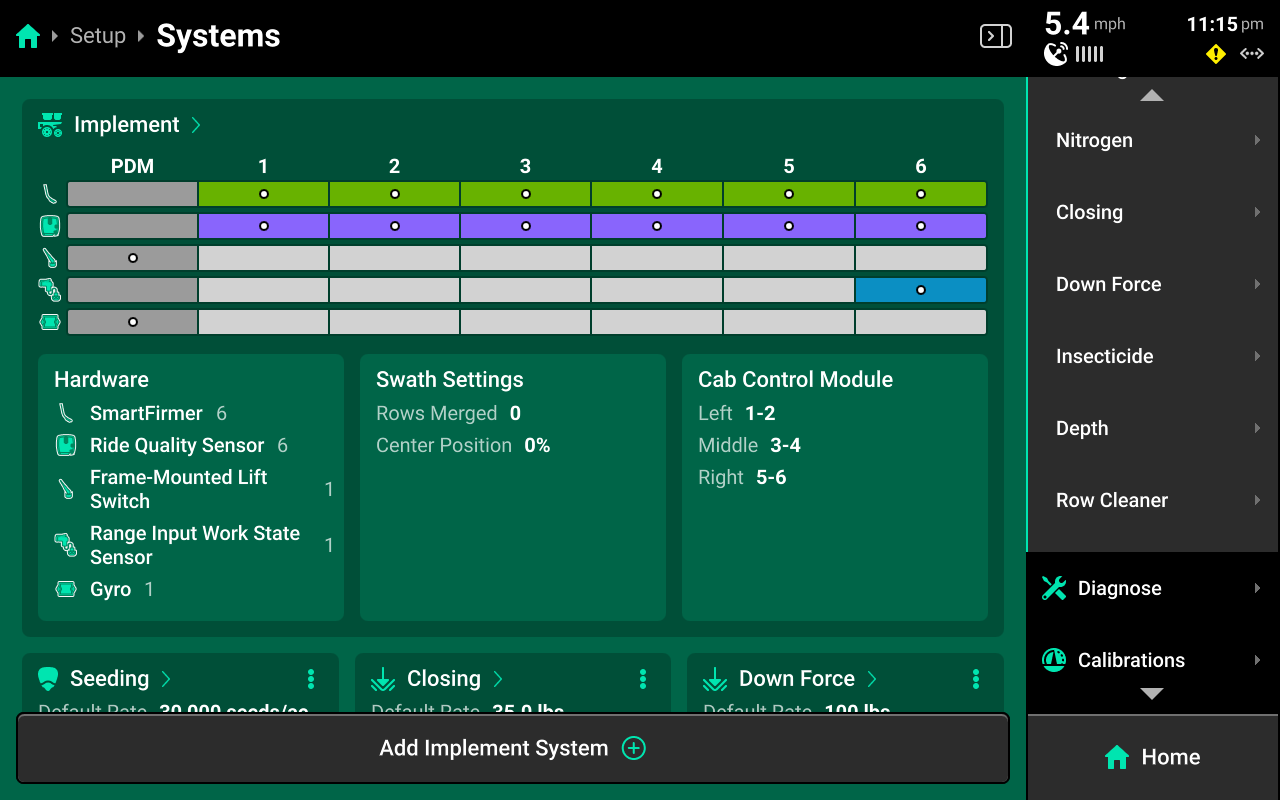

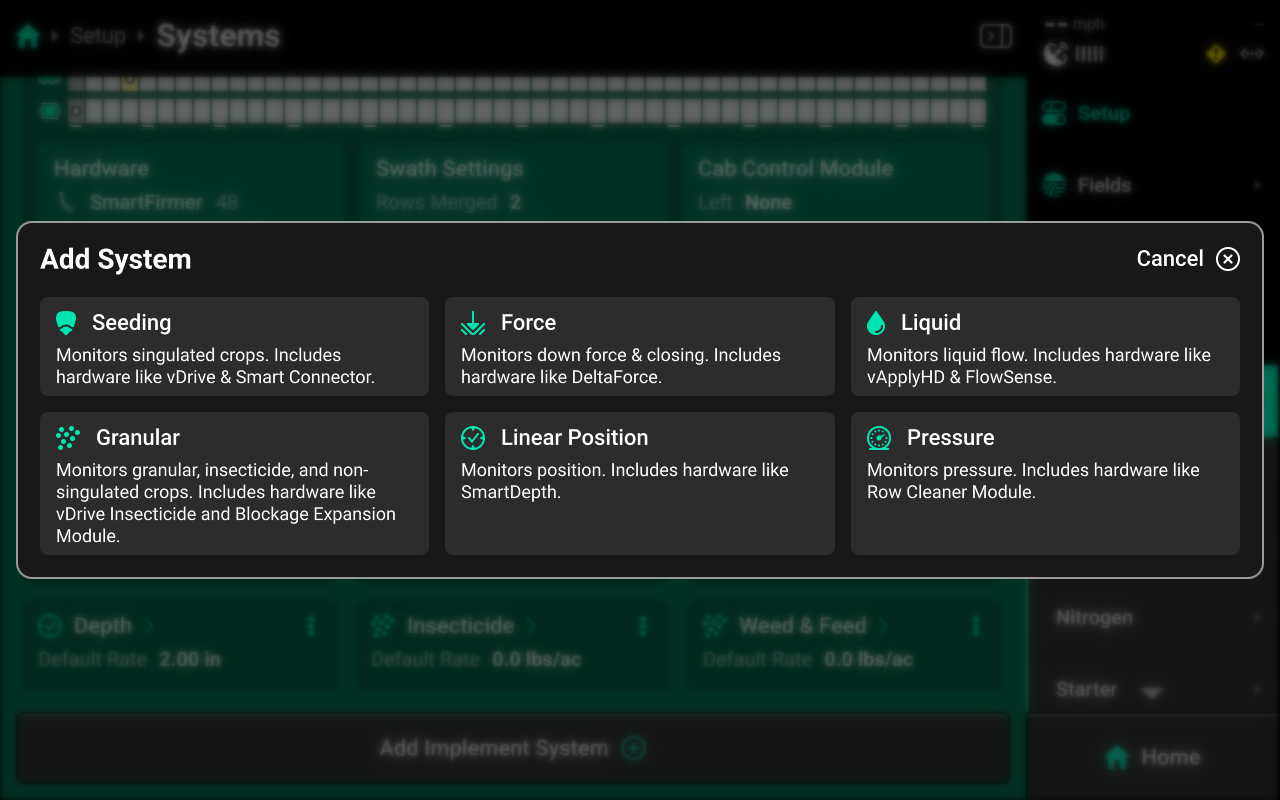

Rate / Swath control requires a Seeding-type System to be configured in the 20|20. To configure a seeding system, Navigate to Setup > Systems and press Add Implement System in the bottom center.

This guide assumes that all Equipment, implement-wide hardware and Ethernet / CAN modules have already been configured and calibrated. See the 2025.1.x Gen 3 Operator's Guide for more details on setting up / calibrating Equipment, Modules and other hardware.

Select seeding from the popup, then select a preset name or enter a custom name from the second popup.

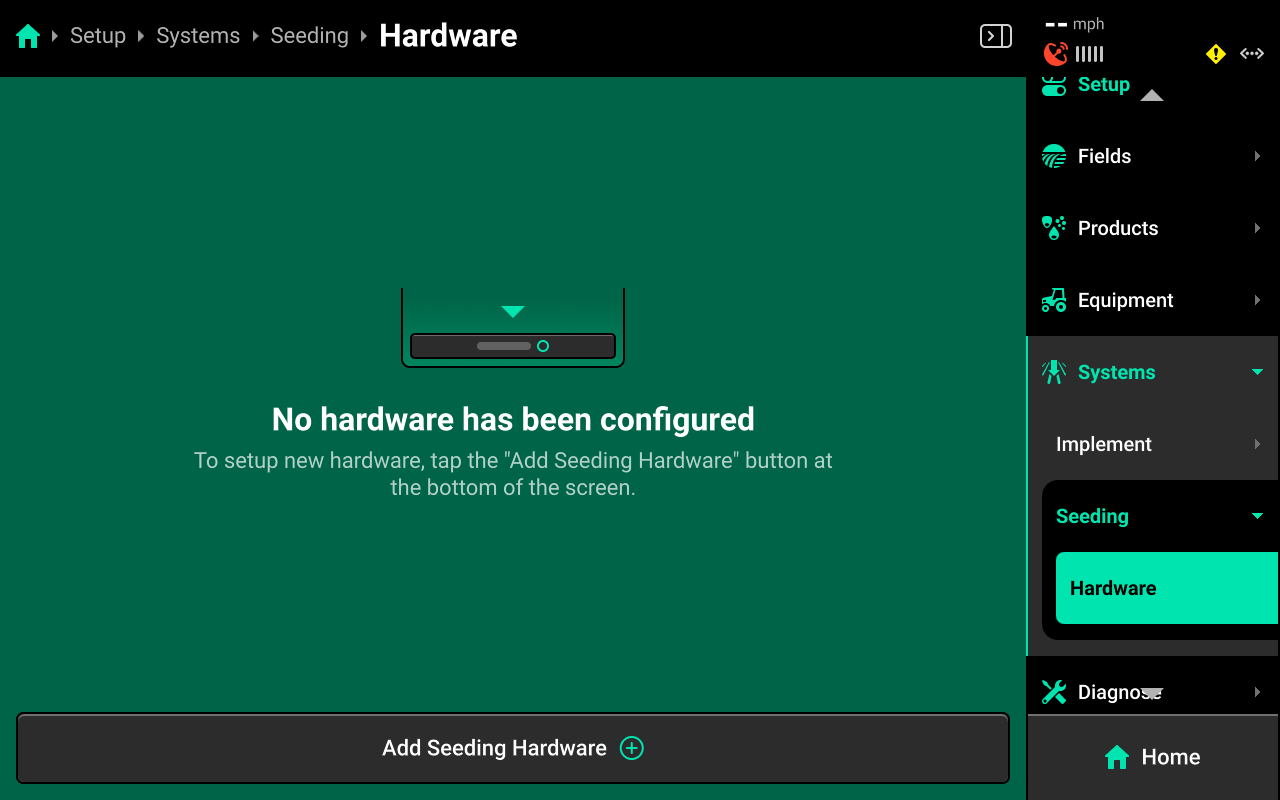

Hardware Setup

To configure Rate / Swath hardware, select [Seeding System Name] in the Navigation Menu, then press Hardware under that system and use the following process.

Rate Controller

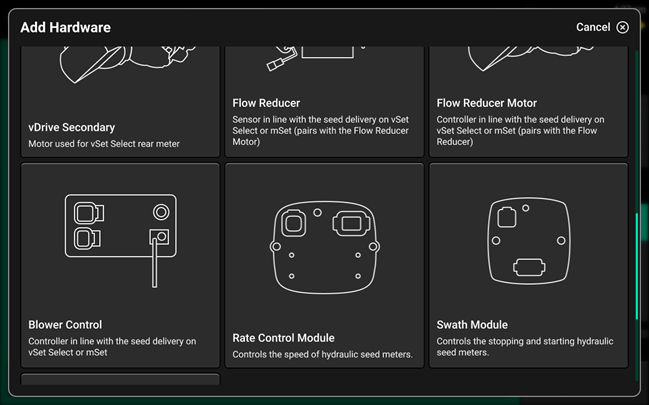

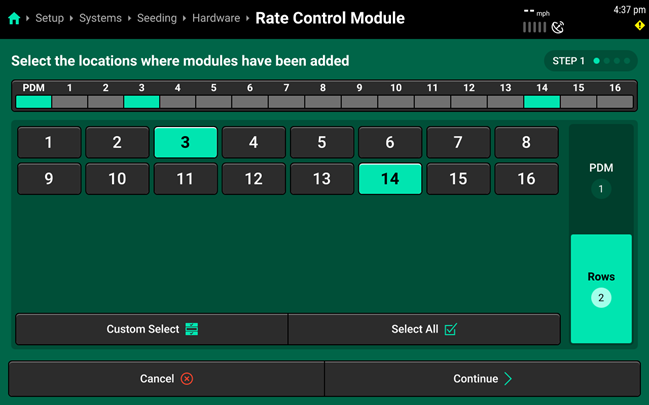

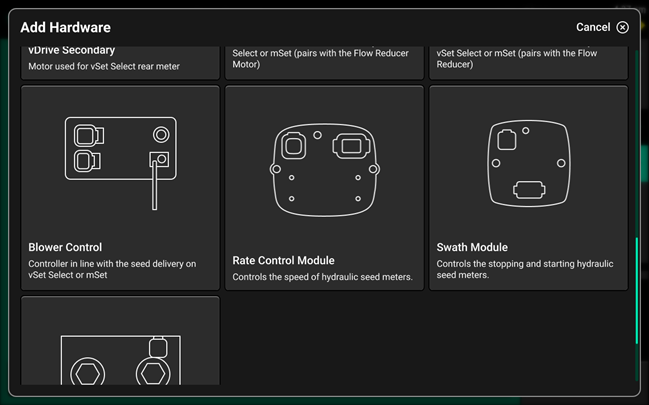

Press Add [System Name] Hardware + and select Rate Control Module [RCM] from the popup to open the RCM hardware setup wizard.

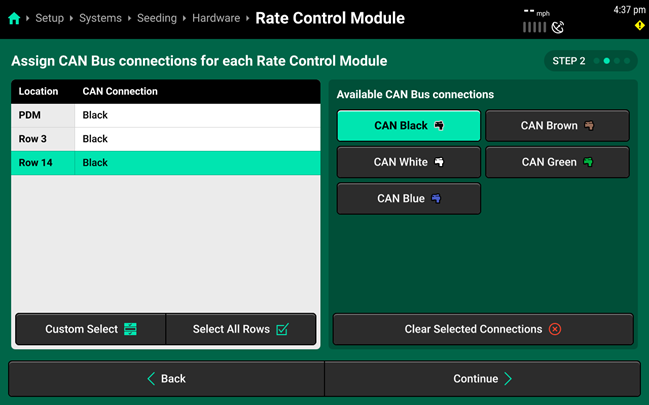

On Step 1, press each row / other location in the table that has a RCM installed, then press Continue.

On Step 2, use the right window to select the jumper color that connects each RCM to the CAN bus. If multiple RCMs are assigned to 1 location, select each jumper color being used. Press Continue when finished.

If more than one RCM is connected on the same row / location, a different jumper color must be used for each RCM.

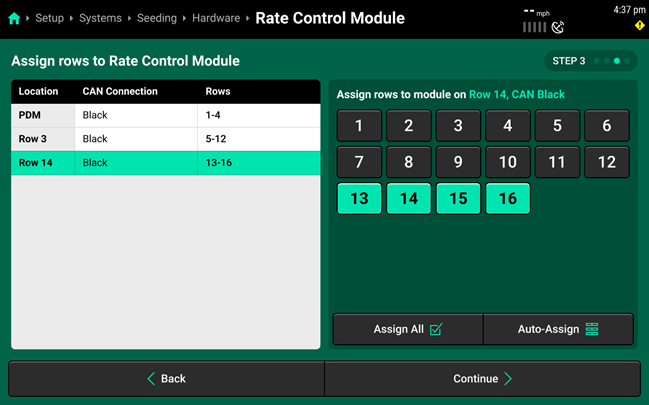

On Step 3, assign the rows which are driven by each RCM to the correct module. Then press Continue.

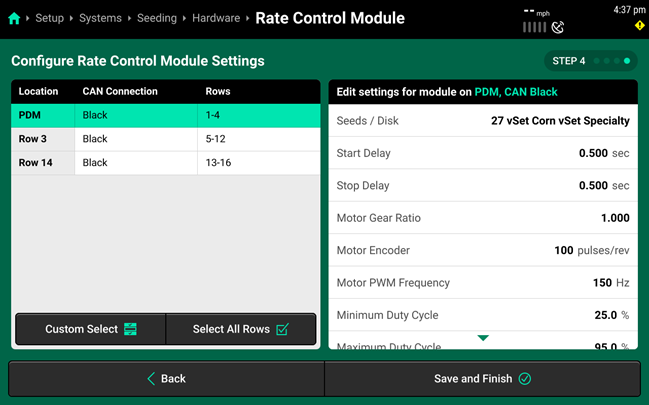

On Step 4 use the left window to select the desired RCM(s), then use the right window to change the desired setting. Press Save and Finish to exit setup.

- Seeds / Disk : The amount of seed cells on the disk that is physically installed in the meter. Select a preset seeds/disk, or press custom and use the pop-up keyboard to enter a custom value.

- Start Delay : The time delay from when the motor starts to when the product reaches the application point.

- Stop Delay : The time delay from when the motor stops to when the product reaches the application point.

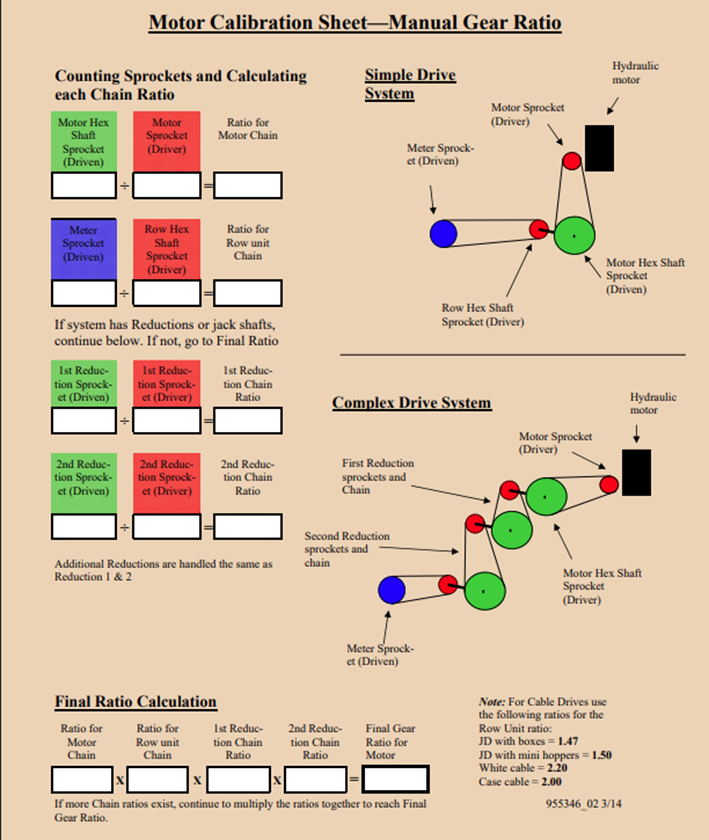

- Motor Gear Ratio : Calculated by dividing driven sprocket by drive sprocket. For information on more complex gear ratio setups, see Appendix A.

- Motor Encoder Pulses / rev : Electric pulses generated per revolution of the motor. Set to 100 for Precision Planting hydraulic motors. See manufacturers’ recommendations for all other motors. Must be set when running Seeding Rate Control.

- Motor PWM Frequency : Frequency needed to control the PWM valve solenoid. The default value of 150hz will work for most systems. Changes should reflect manufacturer specifications.

- Minimum Duty Cycle : The Minimum PWM percentage the user would ever want to run. This setting may need to be changed depending on target application rate.

- Maximum Duty Cycle : The Maximum PWM percentage the user would ever want to run. This setting may need to be changed depending on target application rate.

- Motor Gain : Increasing or decreasing by 0.1 increments increases or decreases the aggressiveness of PWM control. The default value is 1.

Do not adjust Motor Gain unless advised by Precision Planting Product Support.

Swath Module

Press Add [System Name] Hardware and select Swath Module to open the Swath Module setup wizard.

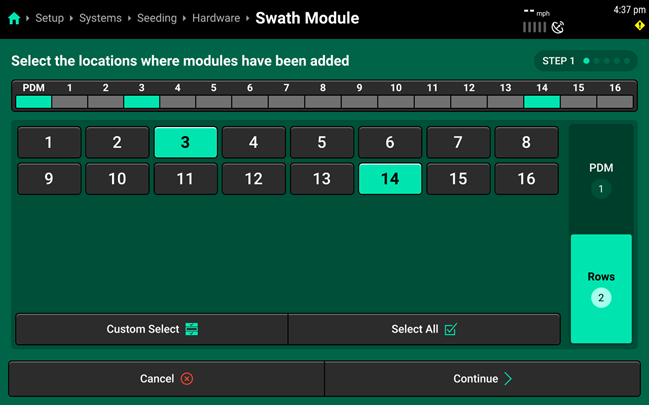

On Step 1, press each row / other location in the table that has a Swath Module installed, then press Continue.

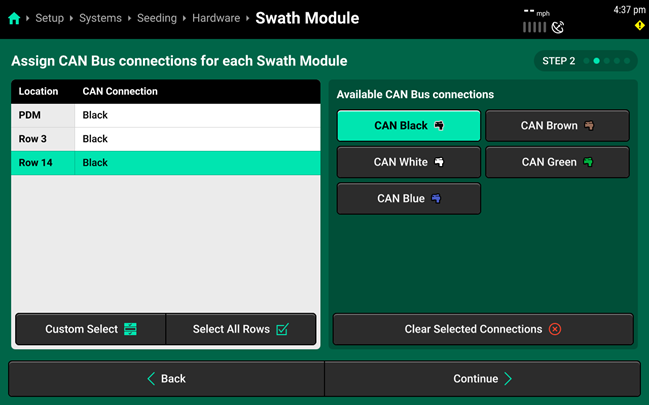

On Step 2, use the right window to select the jumper color that connects each Swath Module to the CAN bus. If multiple Swath Modules are assigned to 1 location, select each jumper color being used. Press Continue when finished.

If more than one Swath Module is connected on the same row / location, a different jumper color must be used for each module.

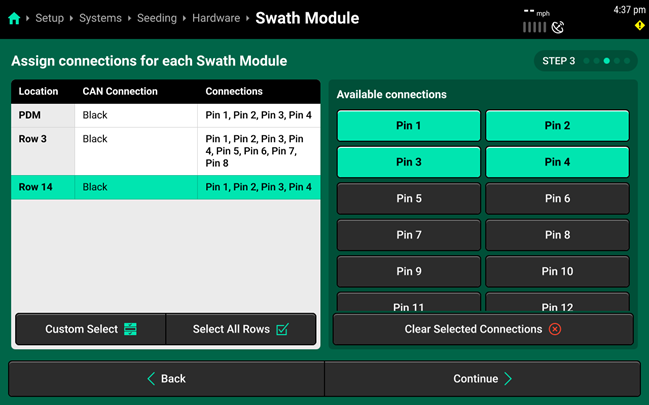

On Step 3, use the right window to select each Swath Module, and the left window to select which pins are being used on each module. Press Continue when finished.

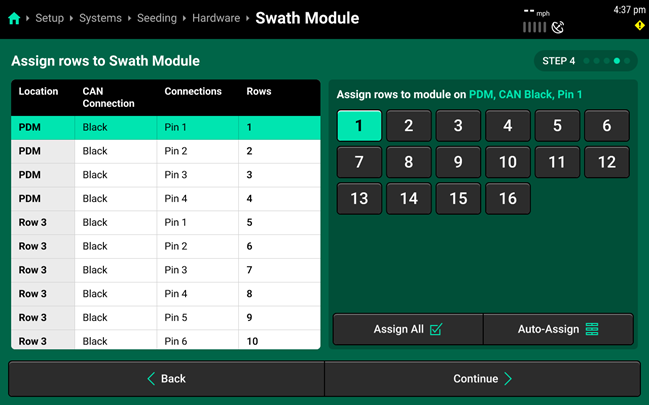

On Step 4, use the right window to select each Swath Module / Pin, and the left window to select which rows will be controlled that pin. Press Continue when finished.

If utilizing the Swath Module to control clutches tied to multiple rows, assign all rows tied to the clutch to the pin.

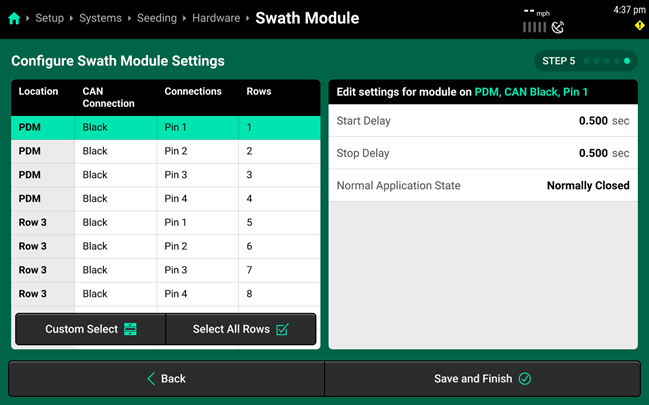

On Step 5, use the right window to select individual pins, and the left window to change the desired setting for that pin. Press Save and Finish to exit setup.

- Start Delay : The time delay from when the motor starts to when the products reach the application point.

- Stop Delay : The time delay from when the motor stops to when the product reaches the application point.

- Normal Application State : Select Normally Open if power is supplied to operate or engage. Select Normally Closed if power is not supplied to operate or engage.

Accessing Hardware Settings

Hardware settings are divided into Install Settings, which are typically adjusted during initial setup, and Operation Settings which may be adjusted multiple times per season / year.

Install Settings are accessible on the final step of each hardware setup wizard, and on the specific system hardware screen after that hardware device is added.

Operation Settings are accessible from the left window of the specific system screen after the hardware device is added. It may be necessary to scroll to view all Operation Settings.

Some Operation Settings are also available under the System Settings tab on the Field Setup screen. This will typically be the simplest way for a user to adjust seeds / disk. See Changing Crop and Seeds / Disk in this guide for more details.

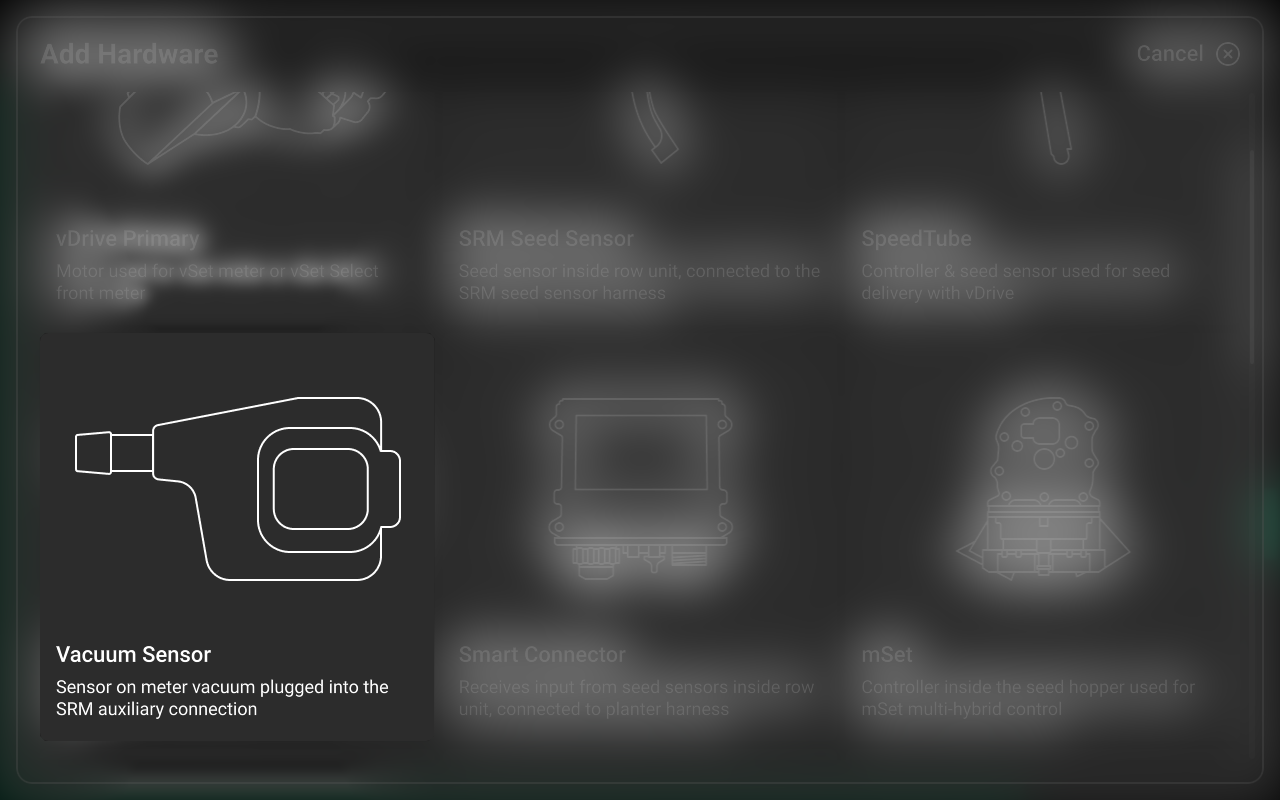

Additional Hardware

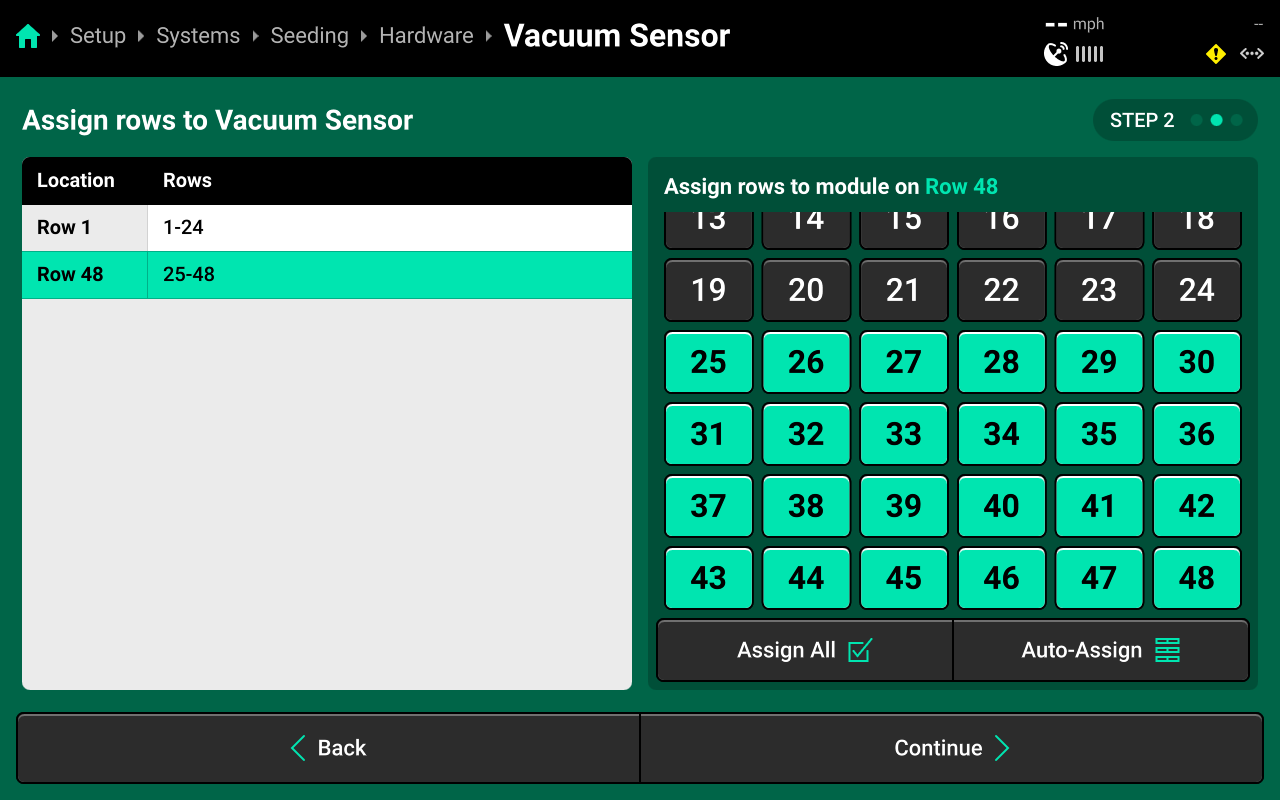

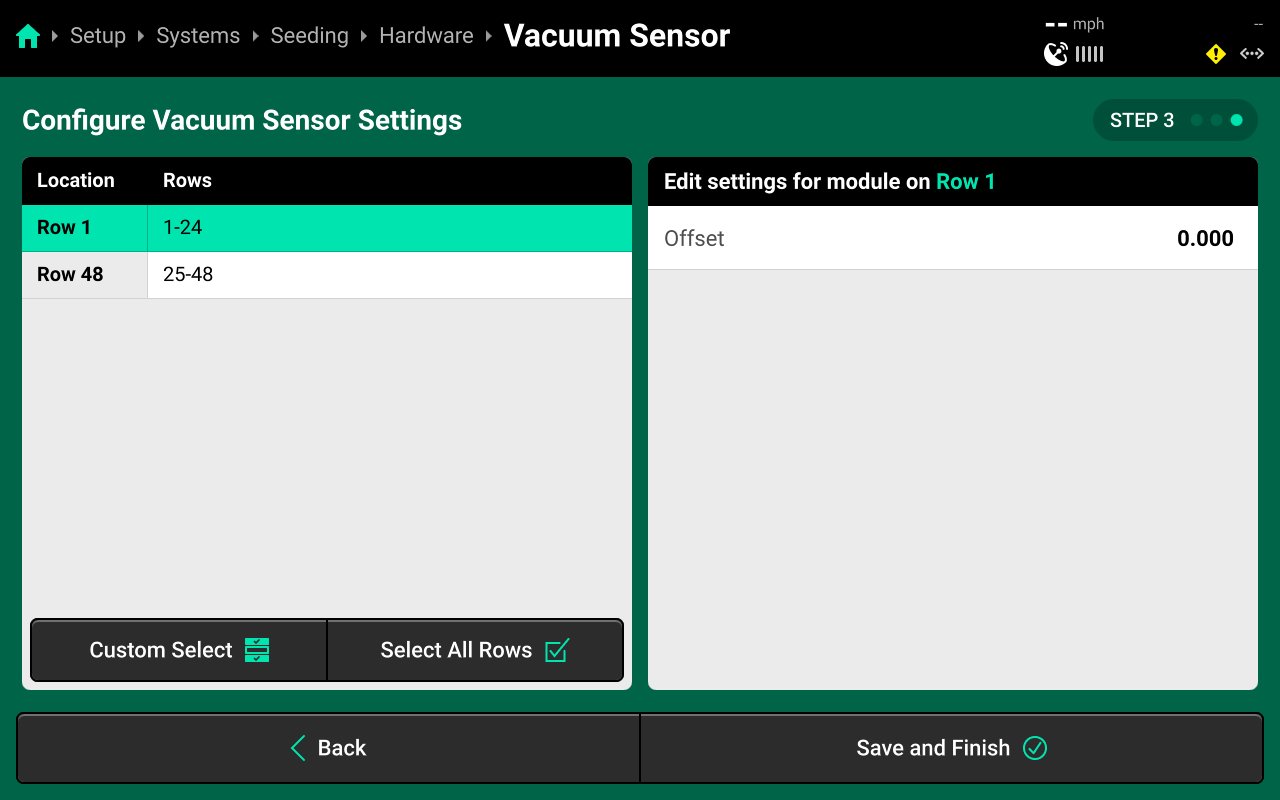

Vacuum sensors may also be added to a seeding system. Rate / Swath control does not require vacuum sensors to function. Use the following process to set up vacuum sensors.

Navigate to the seeding system and select Hardware under the system in the Navigation Menu. Then press Add [System Name] Hardware + and select Vacuum Sensor from the popup.

On Step 1, press each row that has a vacuum sensor installed and press Continue.

On Step 2, select a sensor in the left window, then select all rows that sensor will monitor in the right window. Repeat for each sensor.

Assigning rows to a vacuum sensor allows that row to build on the vacuum map layer on the Home Screen and Panorama. Any row that is not assigned to a sensor will not map.

On Step 3, select one or more rows in the left window, then use the right window to enter an Offset value. Use this setting to zero a sensor with a false reading.

The Offset setting corresponds to the voltage reading on the sensor, not PSI / BAR. Navigate to Setup > Diagnose > Planter > [Seeding System Name] and select Vacuum Sensor to verfiy voltage offset value. Input the value from the Diagnose screen into Offset to zero the sensor.

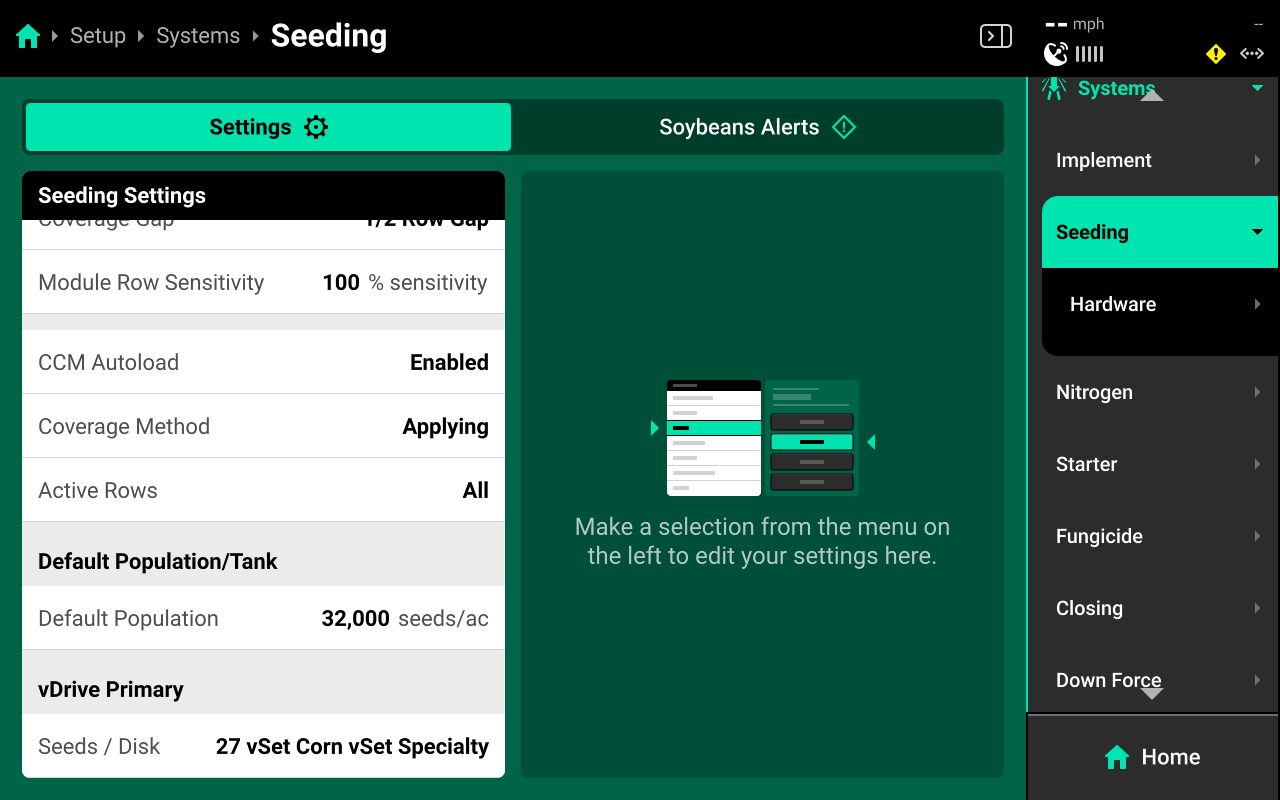

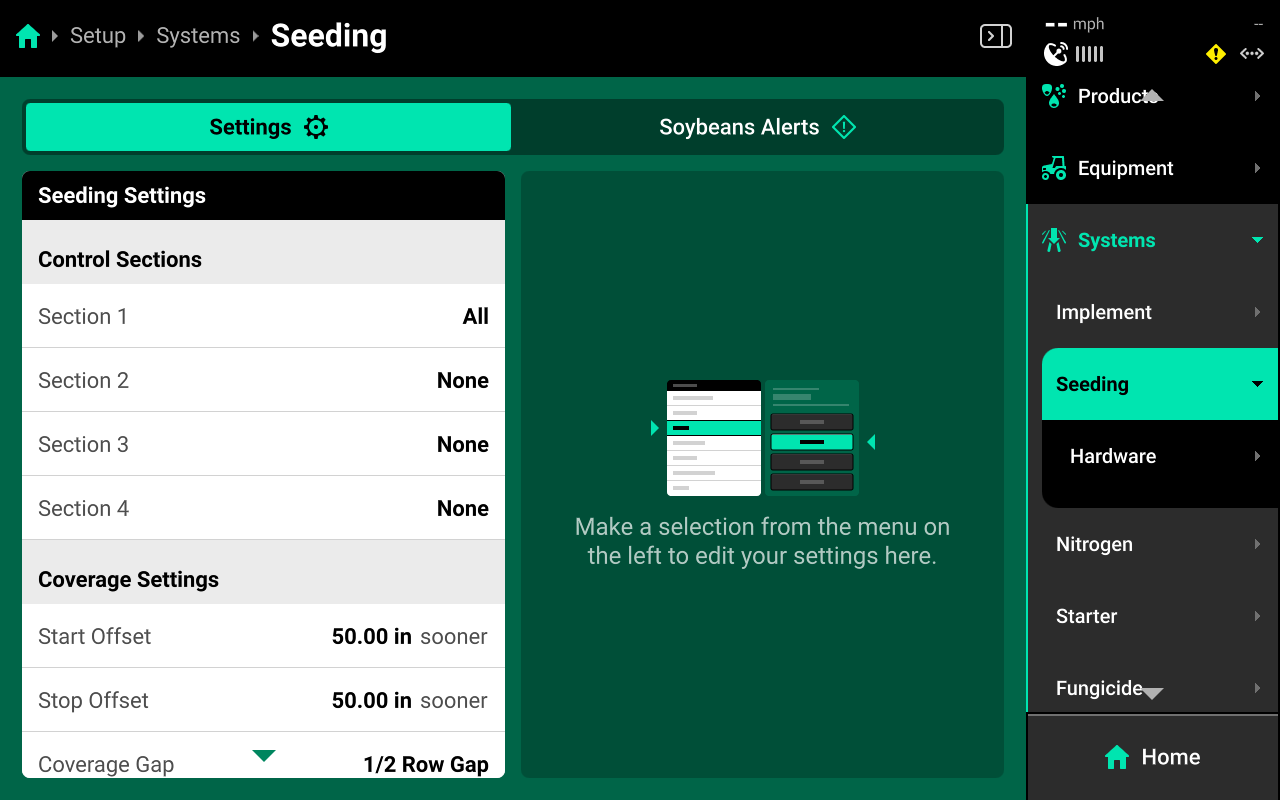

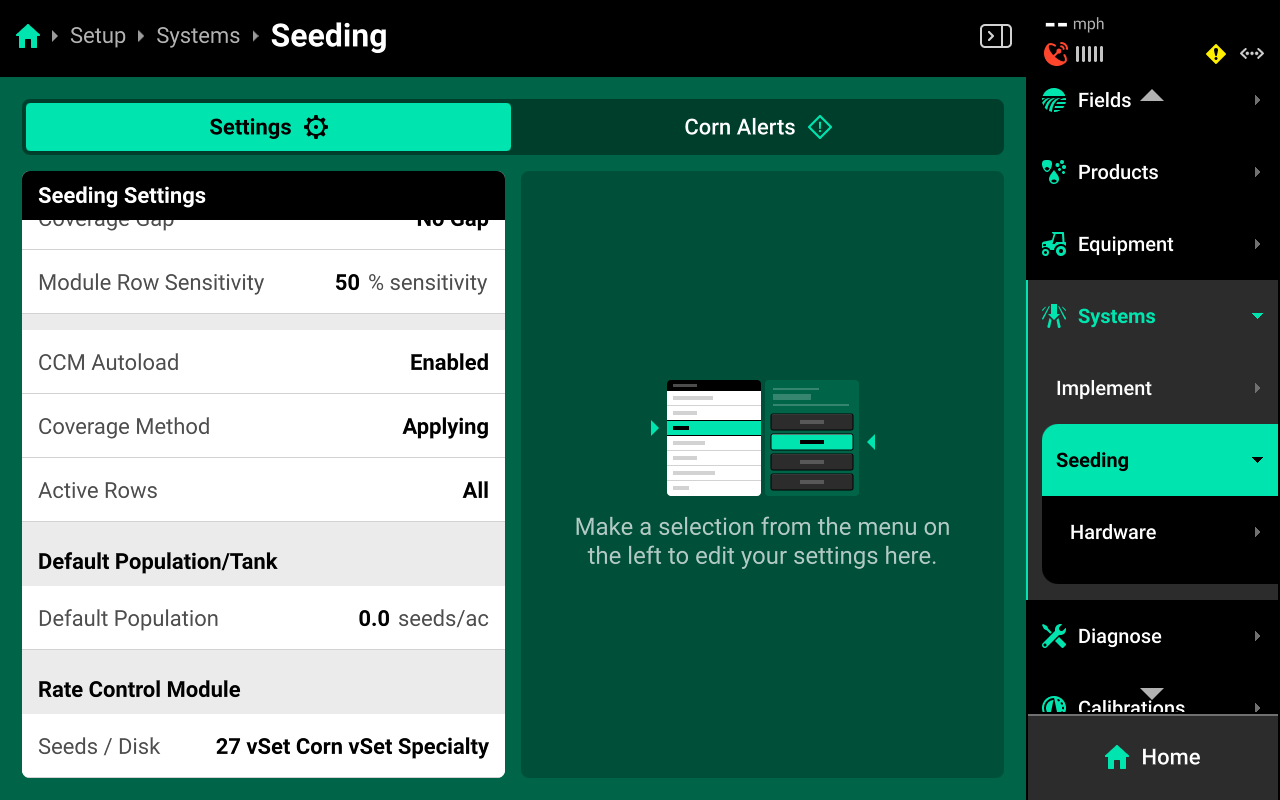

System Settings

After hardware setup is complete, press [Seeding System Name] in the Navigation Menu to adjust system settings.

Additional options will be available after hardware setup is complete. View all options by scrolling on the list.

Select a setting in the left window and modify the setting using the right window.

- Control Sections : Used to set up different rate sections. Select a preset number of rows for each section or use Custom to assign rows manually. Control sections are system-specific. The rates for each control section are adjustable individually or collectively using the system Control widget on the home screen.

- Start / Stop Offset : Used to start or stop planting sooner / later. This setting allows the user to fine tune swathing after performing a GPS offset check.

- Coverage Gap : Used to determine the gap between the swath on / off point and previous coverage. This will be affected by any Start / Stop Offsets. This is determined by Controlled Row Spacing in the planter profile at Setup > Equipment > Planter.

- Module Row Sensitivity : Not typically used with vDrive. Used to determine when a module which applies product across multiple rows (e.g. vApply Base) will swath on / off.

- CCM Autoload : Used to enable / disable autoloading for the system. Any system with this setting enabled will dispense product when the left and right swath switches on the CCM are clicked up.

- Coverage Method : Used to determine when the 20|20 will build Coverage. Any system set to Work State and Applying will not map Coverage unless the lift switch reads lowered. Population and other application maps will still build.

- Active Rows : Sets the active rows for the system. System hardware on any rows not set to active will be deactivated. This setting will typically not be adjusted. To adjust active rows (e.g. when switching from corn to beans on a split-row planter), use Active Rows in the planter profile at Setup > Equipment > Planter.

- Default Population : Sets the out-of-prescription and autoload population for vDrive.

Operation Settings

- Seeds / Disk : After setting up the RCM, this setting will also be available on the System Settings list by scrolling down.

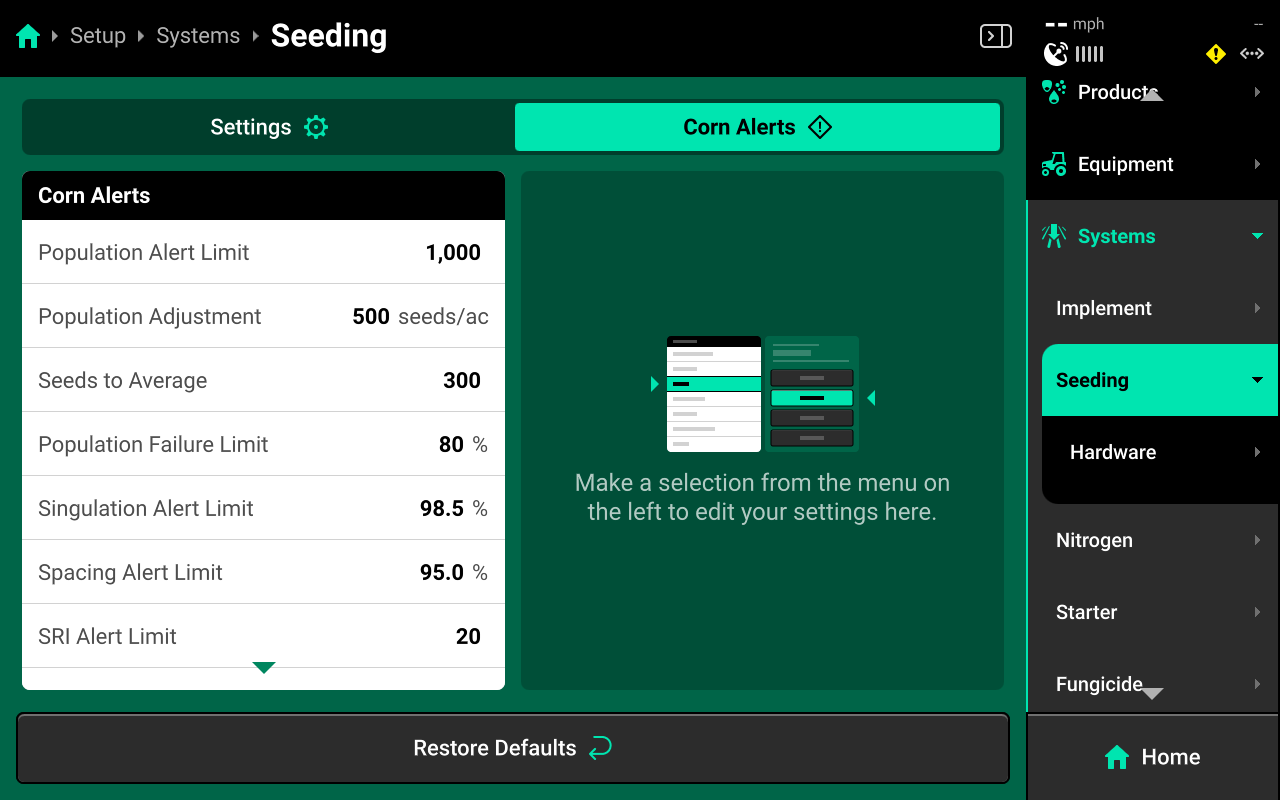

Alerts

Use the tab at the top of [Seeding System Name] to view the crop-specific alerts for the seeding system. Some alerts are adjustable by default, others require the corresponding hardware to be added first. It is advised to add all system hardware before configuring alerts for ease of use. All crops have the same default alert settings, but any changes made will be saved to the specific crop. Press Restore Defaults at the bottom to reset crop alert settings.

Some alerts contain both Alert and Failure limits. The 20|20 will display a popup notification when alert limits are reached, and will perform the action selected for Failure Action when failure limits are reached.

For Rate / Swath control systems, the thresholds for all Alerts correspond to the value that each seed sensor is reading compared to the commanded population.

Optical seed sensors may be affected by physical conditions such as dust and light.

Use the left window to select an alert and the right window to modify its parameters.

- Population Alert Limit : Sets the percent difference from commanded population at which the 20|20 will deliver an alert.

- Population Adjustment : Sets the value by which the quick adjust buttons on the seeding system control screen will adjust population.

- Seeds to Average : Sets the value which the 20|20 will use when calculating the rolling average for population, singulation, spacing, and SRI. It is recommended to use a value that corresponds to 1% of population (e.g. If planting with a population of 30,000, use a Seeds to Average value of 300.).

- Population Failure Limit : Sets the percent difference from commanded population at which the 20|20 will deliver a failure alarm.

- Singulation Alert Limit : Sets the singulation percent at which the 20|20 will deliver an alert. Singulation refers to the percentage of time that the 20|20 detects the release of one seed, rather than a skip or multiple.

- Spacing Alert Limit : Sets the seed spacing percent at which the 20|20 will deliver an alert. Spacing refers to the consistency of distance between each seed drop.

- SRI Alert Limit : Sets the percentage for a Seed Release Index alert. Seed Release Index factors out skips and multiples. The lower the number, the more consistent seed spacing is.

- Rate Failure Action : Determines what action the 20|20 will perform when failure thresholds are reached.

- Jump to Homepage : The 20|20 will go the Home Screen when the threshold is reached.

- Jump to Row Details : The 20|20 will go to the Row Details screen when the failure threshold is reached.

- No Action : The 20|20 will not take any immediate action when the failure threshold is reached.

Changing Crop and Seeds / Disk

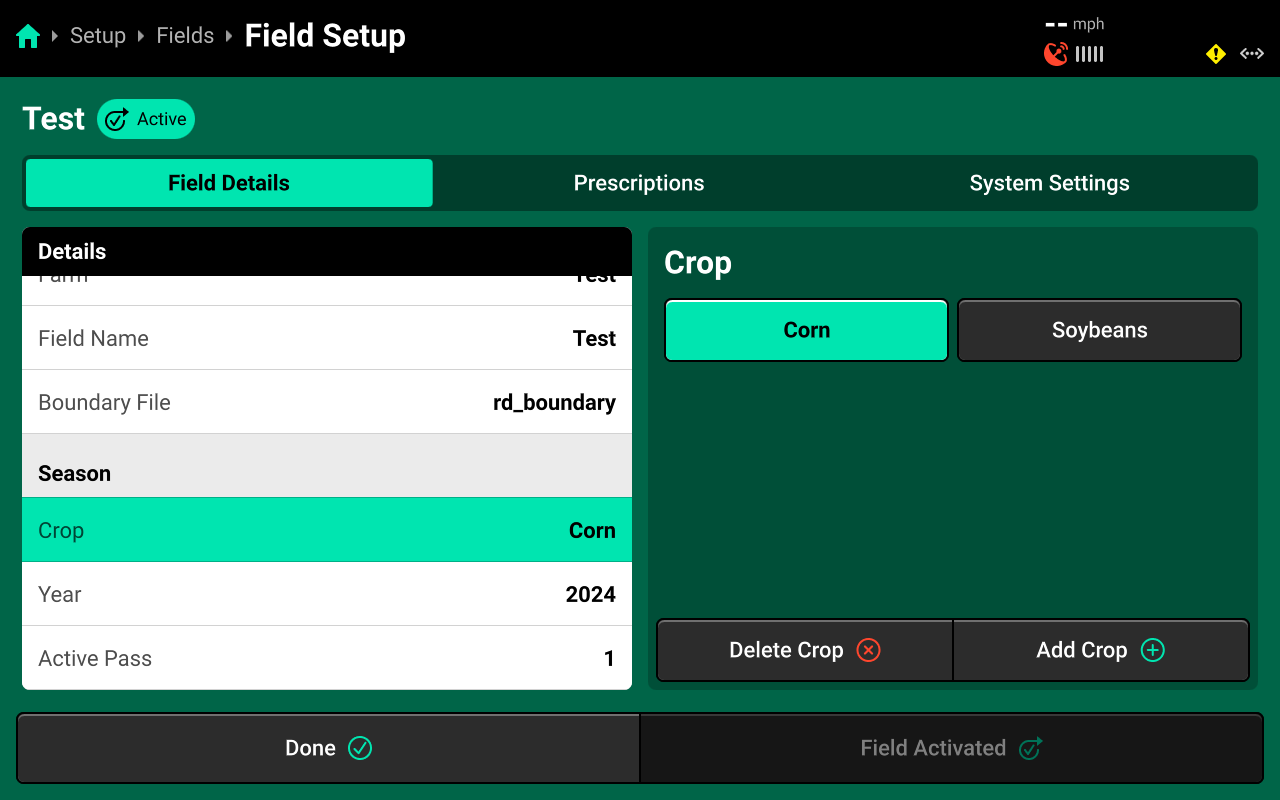

When switching crops in 2025.1.x software, it is necessary to change both the Crop setting and the Seeds / Disk setting. These settings are not tied together as in previous versions of Gen 3 20|20 software.

Crop

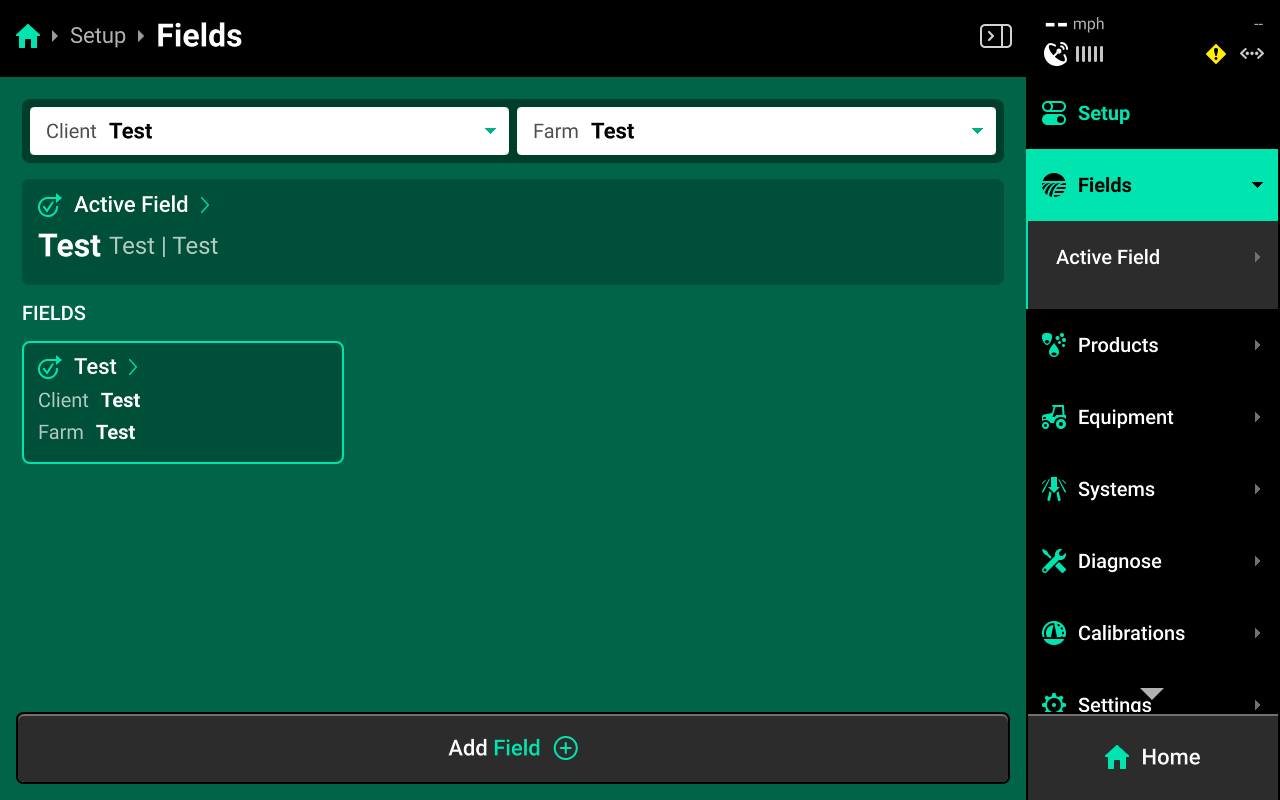

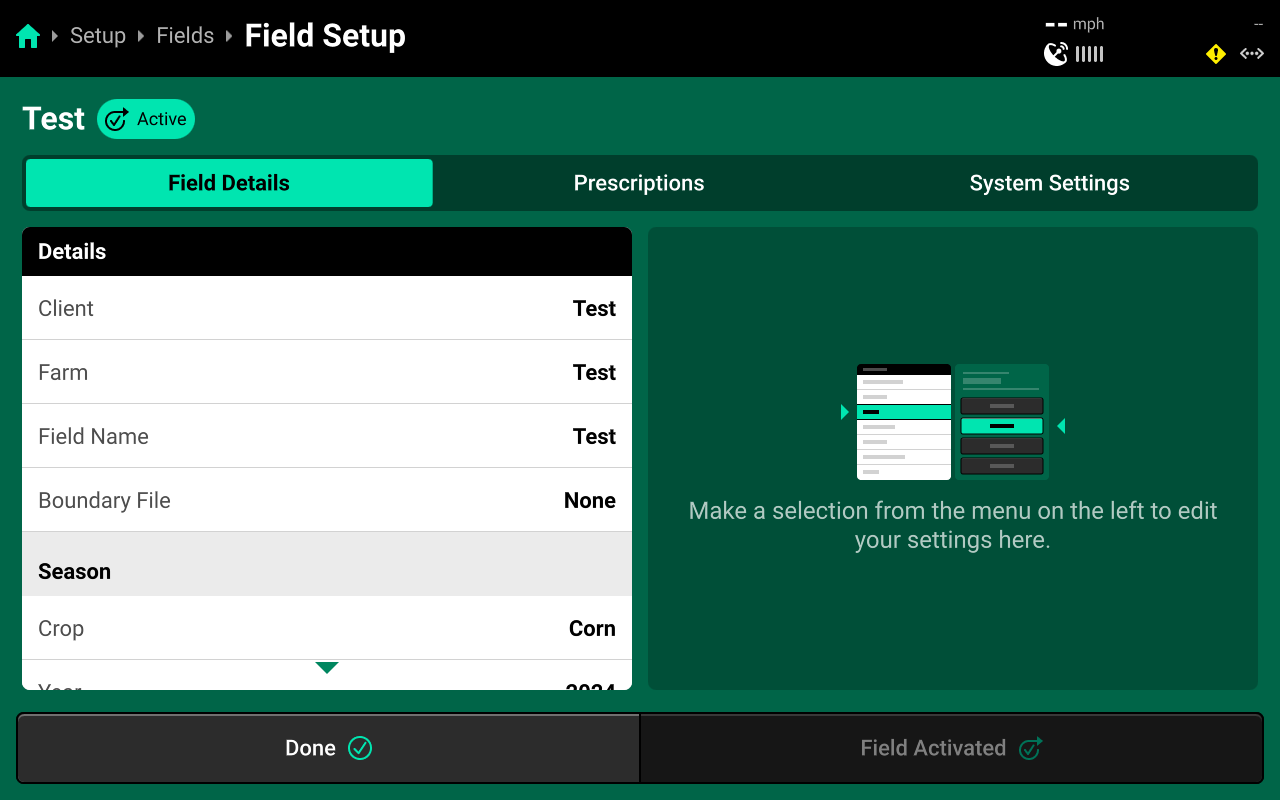

Navigate to Setup > Fields then select the desired field from the table in the center, or press Active Field under Fields in the Navigation Menu.

Scroll down on Field Details in the left window and press Crop. Select the desired preset crop in the right window, or press Add Crop + in the bottom right window and use the popup keyboard to enter a custom crop name.

The Crop setting will only be available on the active field. If the field is not active, press Make Field Active in the bottom right to adjust the Crop setting.

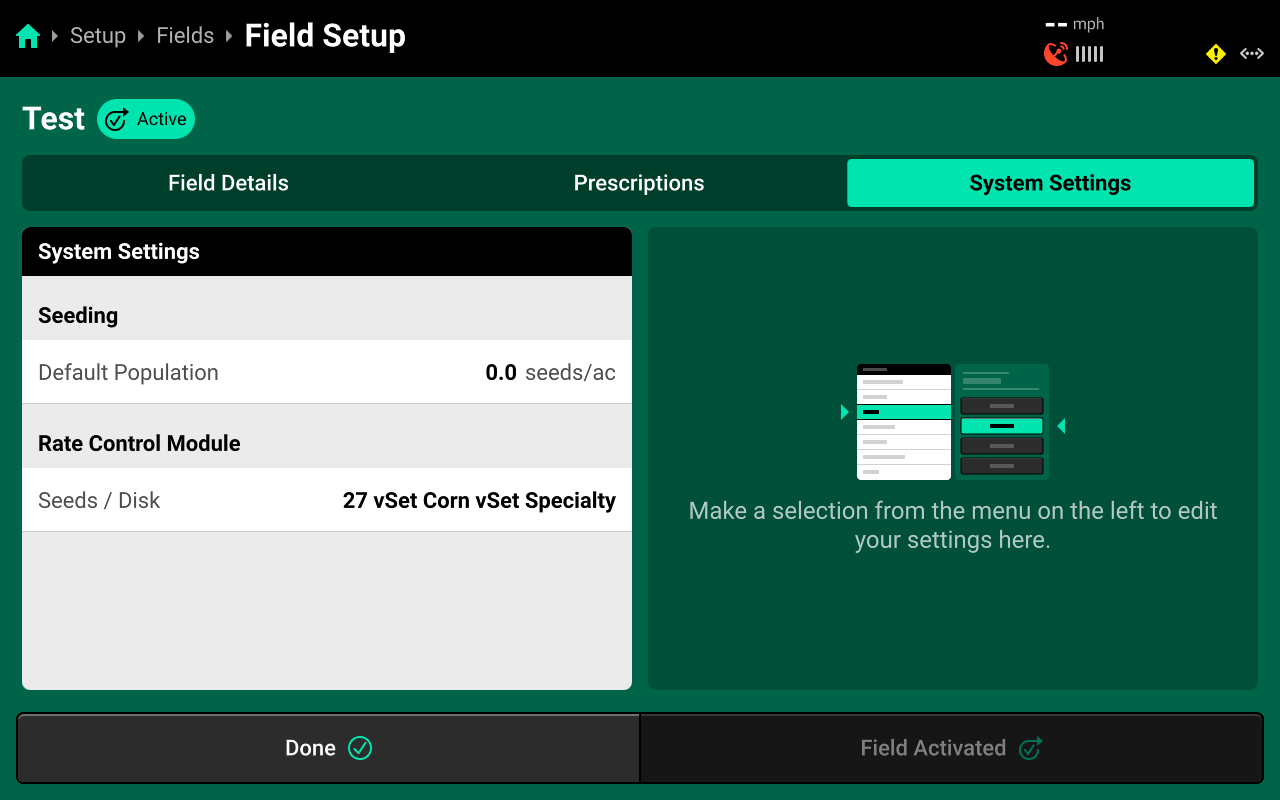

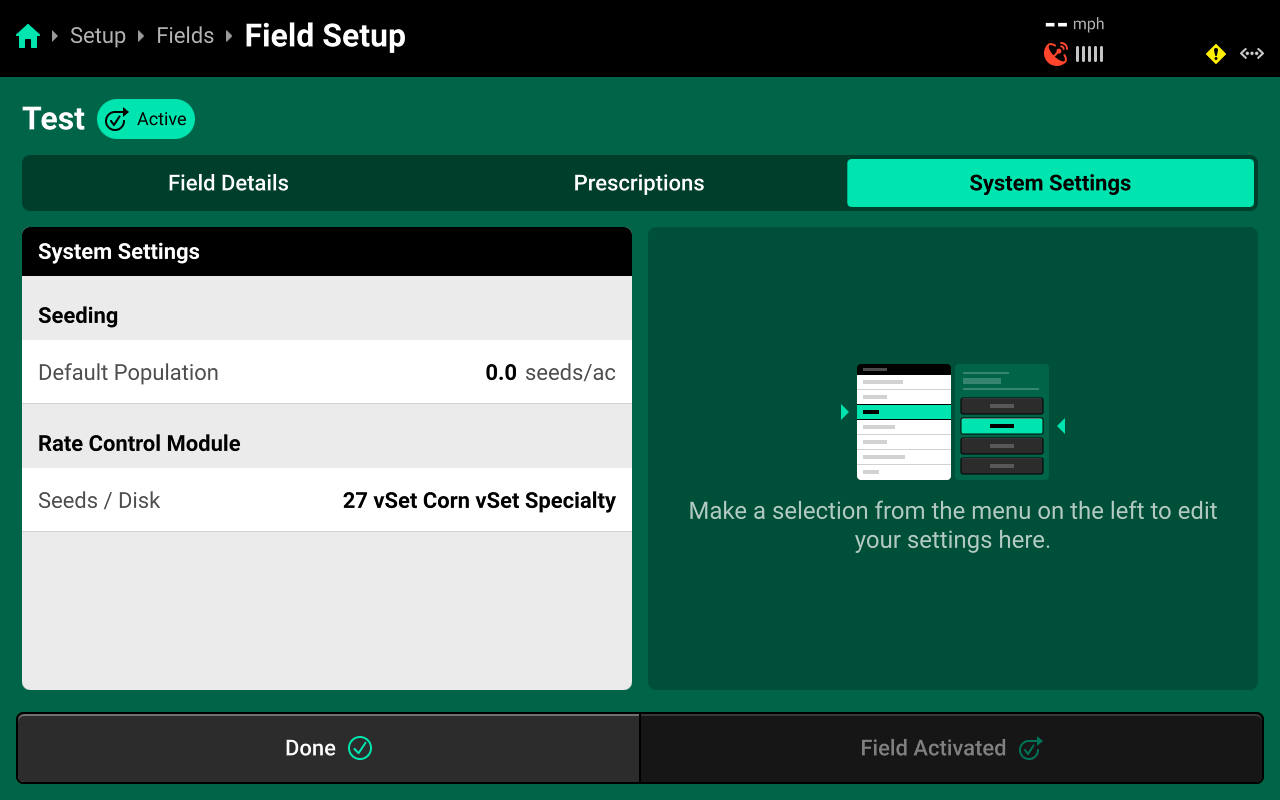

Seeds / Disk

Use the tabs at the top of the Field Setup screen to access System Settings. If vDrive hardware is completely configured, Seeds / Disk will be available from this tab.

Select Seeds / Disk in the left window and select a preset disk, or press Custom in the bottom right to enter a custom seeds / disk.

Depending on other configured systems, other settings may be available on the System Settings tab. It may be necessary to scroll to locate Seeds / Disk.

Seeds / Disk may also be changed from the Systems menu. See Accessing Hardware Settings in the Hardware Setup section of this guide, and the System Settings section of this guide for more details.

Prescriptions and Boundaries

Prescriptions and boundaries must be assigned to each field manually. All prescriptions and boundaries must be imported from an external USB drive into the 20|20 by navigating to Setup > Settings > Import Data and selecting Prescriptions or Field Boundaries. See Import Data in the Settings section of the 2020 Gen 3 Operator's Guide- 2025.1.x Software for more details.

Navigate to Setup > Fields and select the desired field from the table in the center, or select Active Field under Fields in the Navigation Menu.

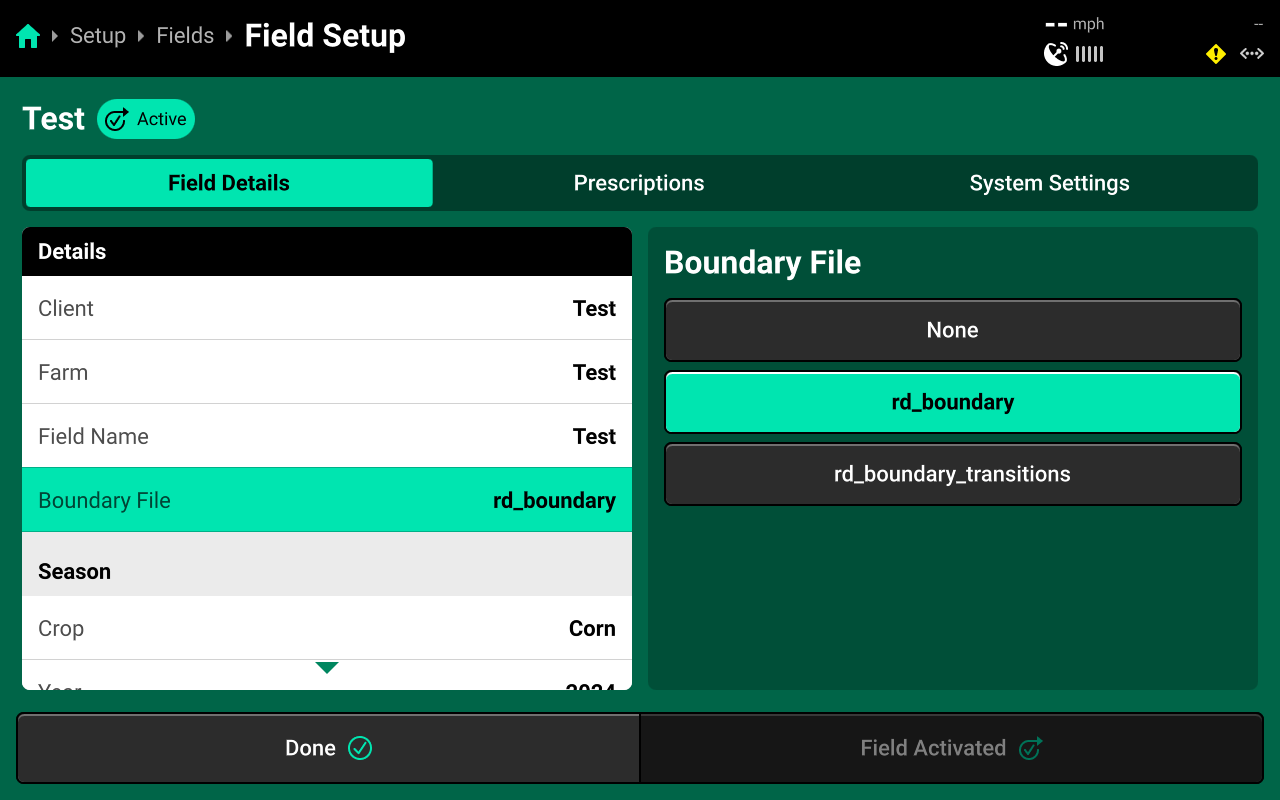

Boundaries

Press Field Boundary in the left window and select the desired boundary in the right window to assign that boundary to the field.

Once assigned, the field boundary will be available as a map layer on the Home Screen.

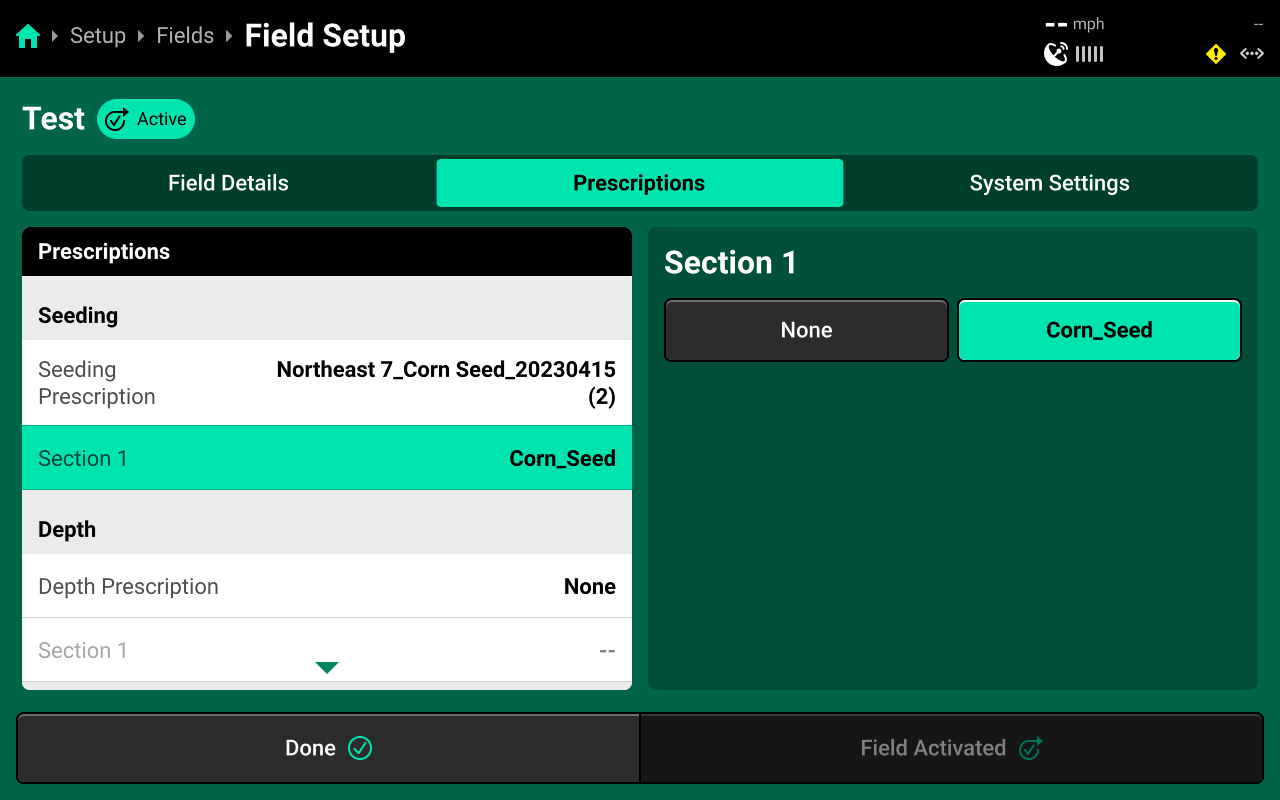

Prescriptions

Press the Prescriptions tab at the top to assign prescriptions.

Press Prescription in the right window and select the desired prescription file from the list in the right window. Then press the desired Rate Section in the left window and select the desired prescription attribute in the right window.

An attribute must be assigned to the desired rate section(s) to engage prescription control.

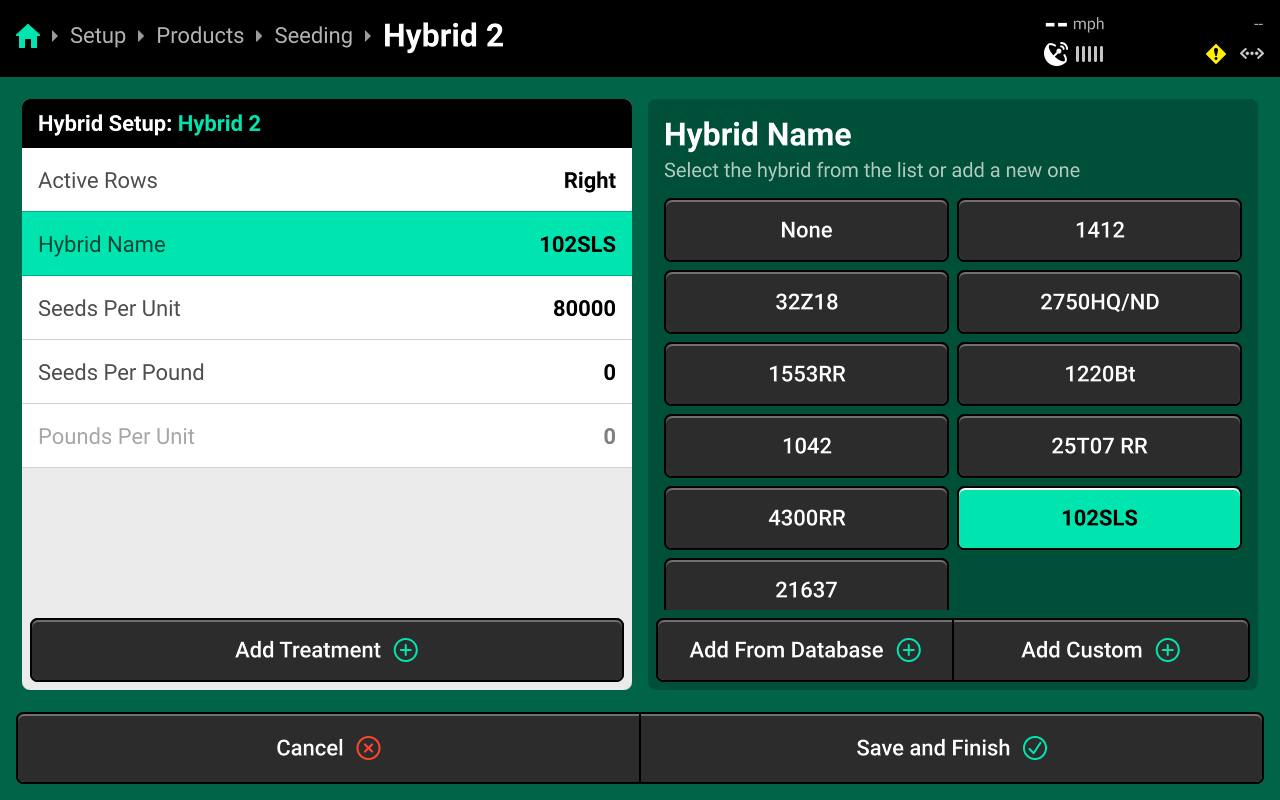

Using Hybrids

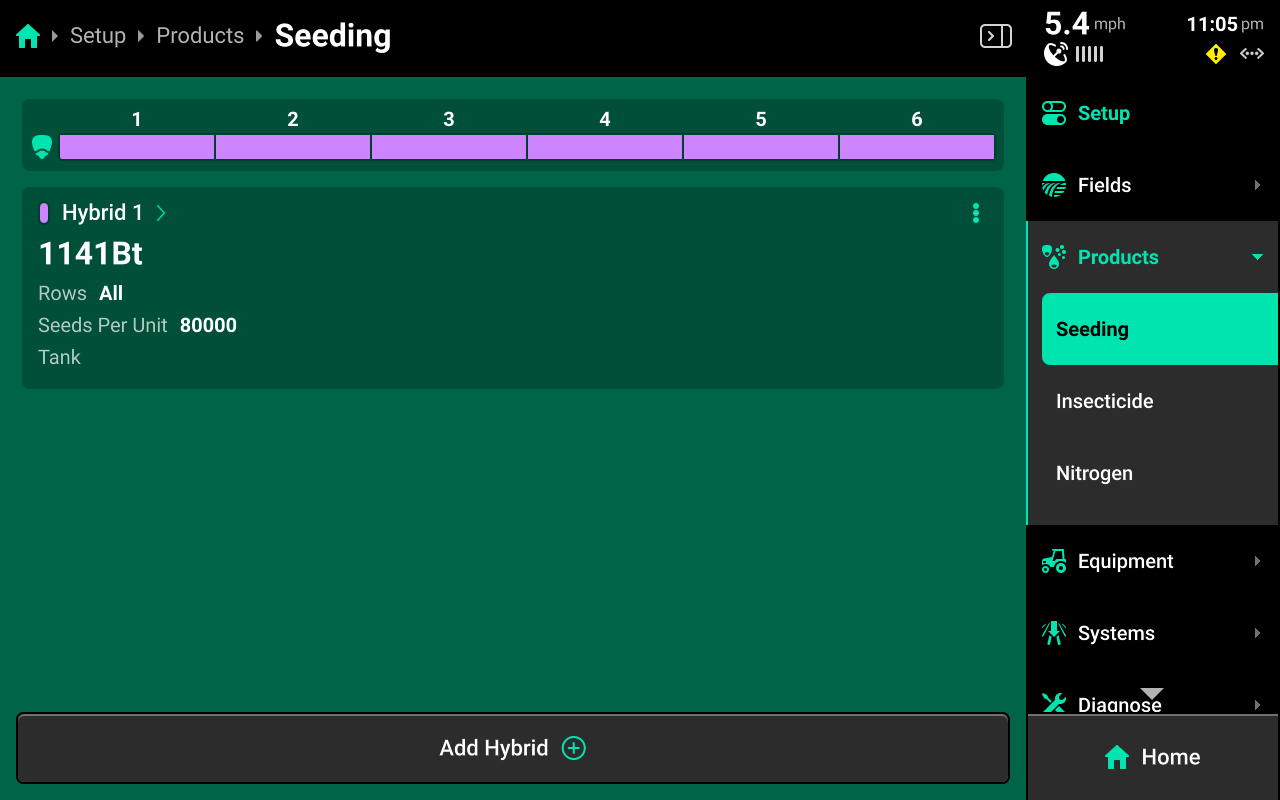

Navigate to Setup > Products and select [Seeding System Name] to add, delete, or modify hybrids.

A table of hybrid entries is displayed in the center. Press Add Hybrid + to immediately add a numbered hybrid entry to this table. Press the three dots next to any entry displayed in the table to delete it.

Press on any entry once it has been added to open Hybrid Setup.

Hybrid Setup Screen

Use the Hybrid Setup screen to select or enter a hybrid name, modify hybrid volumetric attributes, or set the active rows for the selected hybrid.

The Hybrid Name list is limited to 10 names. Adding an eleventh name will remove the oldest name.

Precision Planting Product Support recommends using the table of hybrid entries displayed on Setup > Products > [Seeding System Name] as the "master list" of hybrids, rather than the Hybrid Name list on the Hybrid Setup screen. Select a hybrid entry and modify the active rows to "change" hybrids. Adding / deleting hybrids from the list on the Hybrid Setup screen will not remove saved names for the entries. The list of hybrid entries is saved to the Equipment profile.

Manual Test

Navigate to Setup > Calibrations > [Seeding system name] and press Manual Test to access the Rate / Swath control manual test. This calibration will test the system for correct operation, and should be performed on all new installations and at the start of each season. This calibration will spin the meters, dispensing any seed in the hoppers.

Ensure all conditions in the checklist are met and press Continue.

Press Select All to run calibration on every row or make a custom selection using the table in the center, then press Continue.

Use the + / - buttons to adjust population and speed. Use the tabs at the top of the screen to view diagnostics for the different hardware devices.

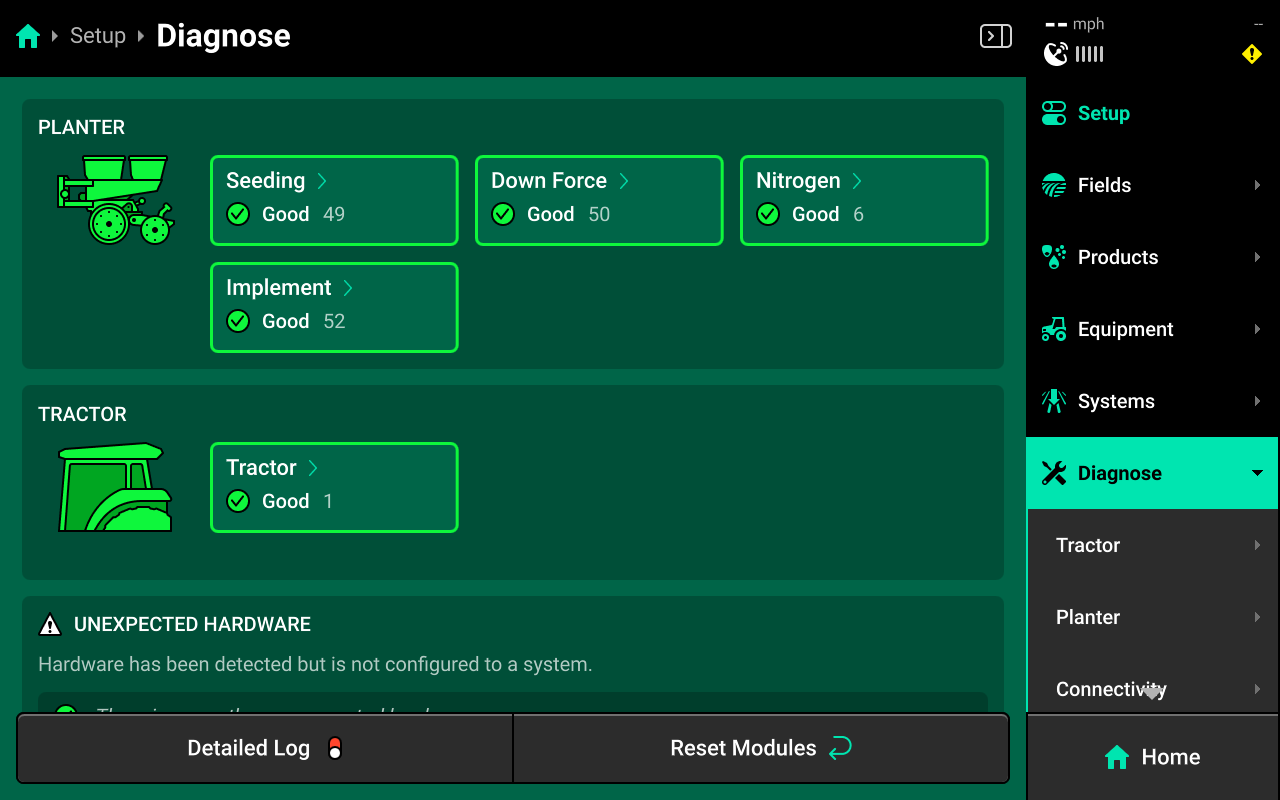

Diagnostics

Diagnose Menu Overview

The Diagnose Menu is used to identify and troubleshoot hardware device failures and configuration issues in the 20|20.

Use the following colors to determine device status on the Diagnose screen.

- Green : Device is working correctly. Communications are good.

- Yellow : Device or sub-component is not 100% functional.

- Red : Device has failed, or is expected and not detected.

- White : Device is detected but not expected.

- Black : Device has been disabled by the user.

- Grey : Device is finishing detecting or unreachable.

- Teal : Device is updating firmware.

Press Reset Modules at the bottom and confirm on the popup to break and reestablish all CAN communication and daisy chain identification. This function is often used as a troubleshooting tool for communication issues.

Due to programming changes for sprayer and seeder compatibility, after pressing Reset Modules or power cycling in software versions 2023.1.0 and above, if a daisy chain break is present in the physical harnessing, all components after the daisy chain break will display red on the diagnose page. The break must be addressed before implement functionality is restored.

Rate / Swath Diagnostics

Information coming soon

Common Troubleshooting Issues

Diagnose screen

Verify hardware health using the color key provided at the beginning of this section. Common issues include:

-

Yellow hardware:

- Command is above or below minimum / maximum capabilities of the module.

- Low supply voltage may indicate damaged power / CAN harnessing, power overdraw (e.g. A large SpeedTube/vDrive system that is not supplied with double APEX power), or damaged hardware.

-

Red hardware:

- Damaged Hardware and / or CAN harnessing.

- Disconnected hardware.

- Misconfigured system setup.

-

White hardware:

- Incomplete system setup.

Physical Diagnostics

Each Swath Module or RCM has a red LED on the end of the motor assembly which will blink with a pattern that indicates vDrive health / status. When troubleshooting, inspect the physical modules to quickly identify possible issues using the LED.

| Light Pattern | Indicated Status |

|---|---|

| No Light | Device Unpowered |

| Solid Light | Updating Device Firmware |

| 5hz Blink | Device Powered, Event Code Active |

| 1hz Blink | Device Healthy |

| Erratic Blink | Device Powered, No CAN Communication |

Appendix A

Gear Ratio Worksheet